In a world that runs on efficiency, boosting production efficiency is essential in manufacturing. So, how can a factory optimize the production process for custom labels to improve efficiency? Which aspects should be focused on to achieve better results? Can efficiency be improved by learning from competitors? Can technical innovations enhance efficiency? Could streamlining personnel management lead to greater productivity?

All these questions can be directly applied to the label production process, but the optimization should be tailored to a company’s specific scale, workforce, financial resources, and technological capabilities. Each business is unique, and solutions should be based on its specific needs. When optimizing label production, companies may need to adjust one or several aspects, but blindly copying others without considering the company’s actual situation may cause more harm than good. The production process is one of the core operations of a company, directly affecting product quality, cost control, and production efficiency. Improving efficiency, reducing costs, and enhancing productivity are all closely linked to a company’s profitability.

Technical Optimization

To enhance a factory’s efficiency, start by creating a production flowchart. This chart clearly displays each step in the production process, the sequence of tasks, and how each phase is interconnected. This enables businesses to analyze where bottlenecks occur, which steps waste resources, and whether any redundant processes or unnecessary costs exist. Can personnel in these areas be further reduced?

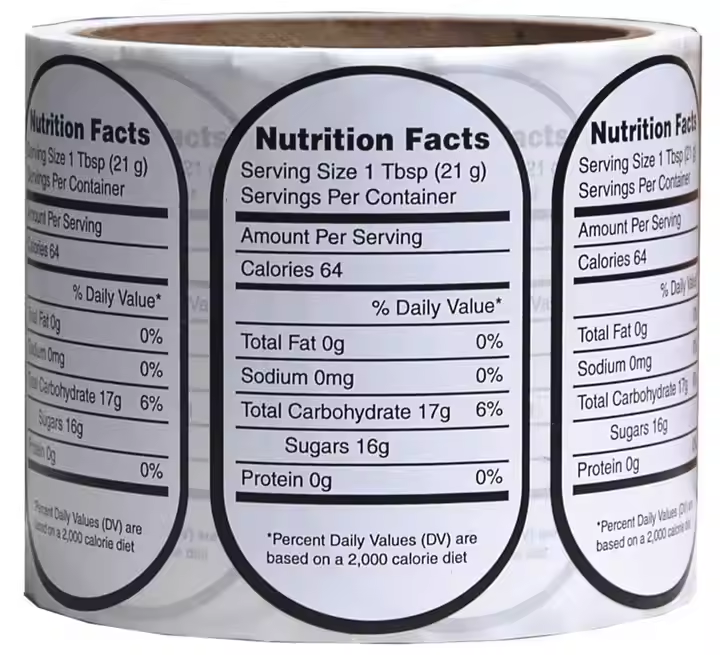

When producing custom labels, factories can optimize their operations by investing in advanced equipment, which significantly increases the speed and efficiency of label production. This allows for a higher output in a shorter period compared to competitors. Technical upgrades are often the most direct and fastest way to optimize a factory’s efficiency. Visiting top-tier factories and learning from their advanced production techniques and methodologies can also help. Discussing with industry leaders or participating in relevant conferences can further improve overall label production efficiency. Moreover, investing in advanced production equipment simplifies the manufacturing process, improves productivity, and reduces the need for excessive staff, ultimately lowering production costs and significantly enhancing factory efficiency.

Design Optimization

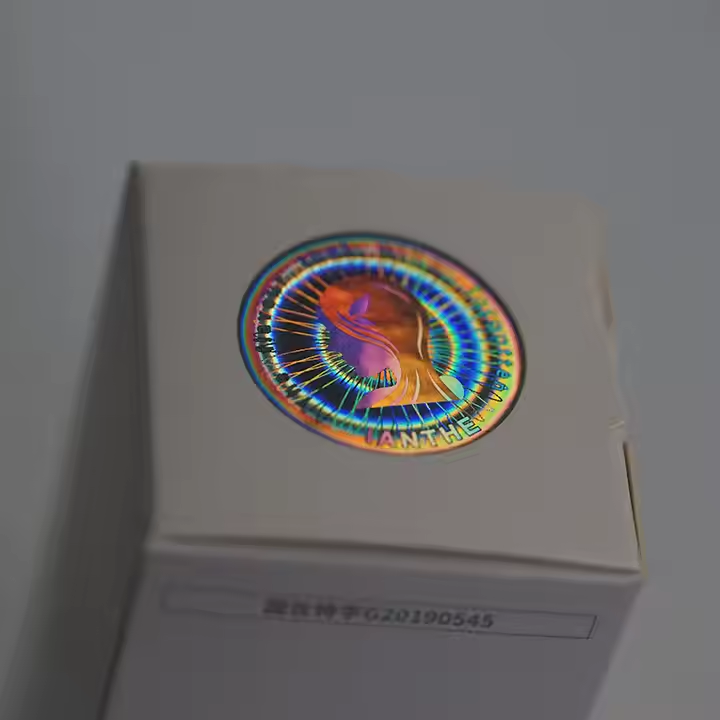

Factories can also optimize the design aspect of the products they manufacture. To attract clients, companies can focus on innovative designs. Good or advanced designs not only capture market attention but also enhance brand visibility. Labels with aesthetically pleasing designs are more likely to gain traction in the industry and become widely recognized, leading to more customers.

In today’s product labeling and packaging industry, the demand for visually appealing designs is higher than ever. As humans evolve, our visual system has become more refined, and consumers now expect higher standards for product labels and packaging. When people browse stores, they are often drawn to items with creative and attractive designs. Capitalizing on this fact, businesses can invest in well-designed labels to grab consumers’ attention.

Companies can allocate more resources to the design department to strengthen the aesthetic capabilities of the team, thereby improving the overall label design standards. For example, when “XiangXiang” shampoo launched a new product, it redesigned the label with a pink bottle and matching pink label, catering to its primary female audience. Since women are the main consumers of “XiangXiang” shampoo, the label’s use of pink successfully resonated with their preferences, leading to wide consumer appeal. This design strategy played a significant role in the brand’s success in the Chinese market, demonstrating how an attractive and consumer-oriented label design can win customer loyalty.

Optimizing Production Management

To optimize or improve the production process, companies can also focus on streamlining the management of production personnel. For instance, Huaxinmei Label and Packaging Company has excelled in this area. If you have label production orders, you can reach out to Huaxinmei for their services. With 18 years of experience in label production, Huaxinmei has developed a professional production team and management system. The company has undergone on-site verification by a world-leading inspection company and offers both OEM and ODM services, providing OEM for renowned brands.

Huaxinmei has also passed 100% FSC certification and holds FSC, UL, and CE certifications, ensuring high-quality label production. These certifications give clients confidence when placing orders. The company supports custom designs based on specific requirements and can help bring your label ideas to life. If your company has only a concept for product labels, Huaxinmei can provide a creative solution tailored to your product’s needs, guiding you from concept to reality.