- Label Design Management

1.1 Customer Communication and Analysis

Establish Communication Channels: OEM/ODM factories need to establish efficient communication channels with customers through meetings, emails, and phone calls to ensure a clear understanding of the customer’s expectations for label design. For example, regular meetings with the brand’s marketing department and product management team can clarify the product information that needs to be displayed on the label (such as ingredients, usage instructions, shelf life, etc.), brand elements (like logos, slogans, etc.), and design styles (such as minimalist, vintage, etc.).

Requirement Analysis and Organization: The customer’s requirements should be analyzed in detail and broken down into specific design demands, such as label size, shape, color, and layout. For example, if the customer requests that the label highlight the natural ingredients of the product, the design should feature the ingredients list prominently, perhaps with larger font sizes or special colors to emphasize it.

1.2 Design Process Management

Internal Design Team Collaboration: If the factory has its own design team, a clear design process should be established. Designers should create the initial draft based on customer requirements, and during the design process, team members should communicate and collaborate thoroughly. For instance, graphic designers handle the overall visual design, while copy editors verify the accuracy of product information and wording. Together, they discuss how to optimize the design for both aesthetic appeal and effective communication.

Design Review and Modification: After completing the initial design draft, it should undergo multiple rounds of review. First, the internal design team reviews the draft to ensure it complies with design standards and customer requirements. Then, it is submitted to the customer for review. Based on customer feedback, modifications are made. This process may involve several iterations until the customer approves the final design. For example, the customer may request changes in the size or color of the logo to better align with the overall packaging style.

1.3 Adherence to Design Standards and Guidelines

Industry Standards: The factory must ensure that the label design complies with relevant industry standards and regulations. For example, food labels must follow food safety regulations, clearly indicating nutritional content, production dates, expiration dates, etc. Cosmetic labels must include ingredients, effects, usage instructions, and precautions. The design must also comply with general printing standards, such as font sizes that ensure readability and safety warning symbols that meet prescribed patterns and color standards.

Brand Requirements: The design must strictly adhere to the brand’s guidelines. Brands usually have their own brand image rules, including logo usage guidelines, color standards, and font requirements. For example, the brand may specify the minimum size of the logo, Pantone color numbers for specific colors, and authorized fonts. The factory must follow these specifications to maintain consistency and professionalism in the brand’s image.

- Label Printing Management

2.1 Printing Supplier Selection and Evaluation

Supplier Selection: The factory should look for printing suppliers with a good reputation, advanced equipment, and rich experience. Market research and peer recommendations can be used to create a list of potential suppliers. The factory should conduct an initial evaluation, which includes reviewing the supplier’s equipment (such as high-precision digital printers or flexographic printers), production capacity (such as daily output, maximum print size, etc.), and quality control systems.

On-site Inspection and Sample Testing: After selecting suppliers, the factory should conduct on-site inspections of their production facilities, checking the condition of the equipment, the maintenance status, and the proficiency of workers. The factory should also request sample prints to test print quality, such as color accuracy, registration precision, and ink adhesion. For example, if high-resolution images are required for the label, sample prints should be tested to evaluate whether the supplier can meet the requirements.

2.2 Printing Process Selection and Control

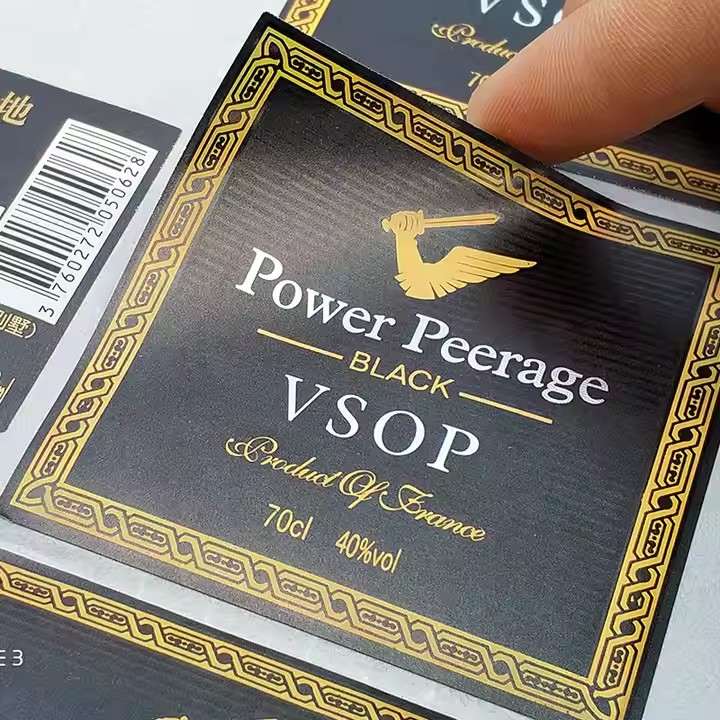

Selecting the Right Process: Different label designs and product requirements call for different printing processes. For example, a simple text-and-graphic label may only require a one- or two-color letterpress printing process, which is more cost-effective. For labels that require high-quality, full-color images, such as cosmetic or premium food labels, digital printing or offset printing may be needed, as these processes provide finer color details and higher resolution.

Printing Parameter Control: During the printing process, it is crucial to control various printing parameters. This includes ink formulation (such as color, viscosity), printing pressure, and printing speed. For example, ink colors should match the color specifications from the design files, and the factory can use color management systems to adjust the ink. Regular color calibration should be performed during the printing process. The printing pressure should be adjusted according to the thickness of the label material and the printer’s performance to ensure even ink transfer and avoid issues like blurry prints or misalignment.

2.3 Quality Inspection and Control

Inspection During Printing: Quality control personnel should conduct regular inspections during the printing process. They should check whether the printed colors match the standard by comparing with the standard color samples or digital color proofs. They should also check the clarity of the images and text, looking for issues like blurring or jagged edges, and verify the registration accuracy, ensuring that different colors align correctly. For multi-color printing labels, registration errors should be controlled within a specified range, such as ±0.1mm.

Finished Product Inspection: After printing, the finished labels should undergo a comprehensive inspection. In addition to the checks mentioned above, the label’s dimensions should be verified, ensuring proper cutting and whether the adhesive meets the required standards. Special labels, such as waterproof labels, should undergo waterproof performance testing, while anti-counterfeit labels should be tested for their anti-counterfeit features. Only labels that pass these quality checks can move on to the packaging stage.