I. Core Dimensions in Jewelry Barcode Label Material Selection

The material of jewelry barcode labels can be broken down into three main components: substrate, coating, and adhesive. The performance of each part directly determines the overall quality of the label, and must be matched according to the jewelry’s material (metal, jade, gemstones, pearls, etc.), type (rings, necklaces, bracelets, pendants, etc.), and application scenarios (counter display, warehouse management, logistics).

- Substrate: Defines the Label’s Basic Performance and Adaptability

The substrate serves as the “structural backbone” of the label. It must provide sufficient strength, flexibility, and durability, while avoiding chemical reactions with jewelry surfaces. Common substrates fall into two categories: paper-based and film-based, each suited to different scenarios.

Paper-based substrates (e.g., coated paper, matte paper) offer low cost and high print clarity, making them suitable for short-term use (such as promotional jewelry or fashion silver accessories). However, they lack water and abrasion resistance, requiring lamination (gloss or matte) to improve durability. Note that paper substrates are only suitable for non-contact display jewelry (e.g., showcase pieces or packaged items). They should not be applied directly to jewelry surfaces, as paper fibers can scratch plated layers (e.g., K-gold, gold plating) and become sticky when damp, leaving residue that is difficult to clean.

Film-based substrates are the mainstream choice, including polyester (PET), polyvinyl chloride (PVC), and polypropylene (PP).

PET: High hardness, heat resistance (80–120℃), and tensile strength, ideal for long-term labeling on metal jewelry (e.g., platinum, silver rings), with no oxidation issues.

PVC: Highly flexible and cold-resistant (remains pliable at -20℃), suitable for jewelry with curves (e.g., bracelets). Only lead-free, eco-friendly PVC should be used to avoid heavy metal contamination.

PP: Lightweight, chemical-resistant (sweat, perfume, etc.), suitable for body-worn jewelry (e.g., pendants, earrings). Leaves no adhesive residue after removal, preventing surface damage.

- Coating: Ensures Barcode Readability and Durability

The coating, applied to the substrate’s surface, acts as the “information carrier layer” for barcode printing. It must support high resolution, scratch resistance, and fade resistance to ensure barcodes remain scannable even after repeated handling.

For paper substrates, ink-absorbent resin coatings are preferred, paired with wax or resin ribbons to prevent ink bleeding. For humid environments (e.g., Southern China’s rainy season), additional waterproof coatings (e.g., acrylic) are required.

For film substrates, coatings should support thermal transfer or UV printing.

Thermal transfer coatings (resin ribbon compatible) provide excellent scratch resistance (withstand 500+ rubs). Suitable for warehouse labels with frequent scanning.

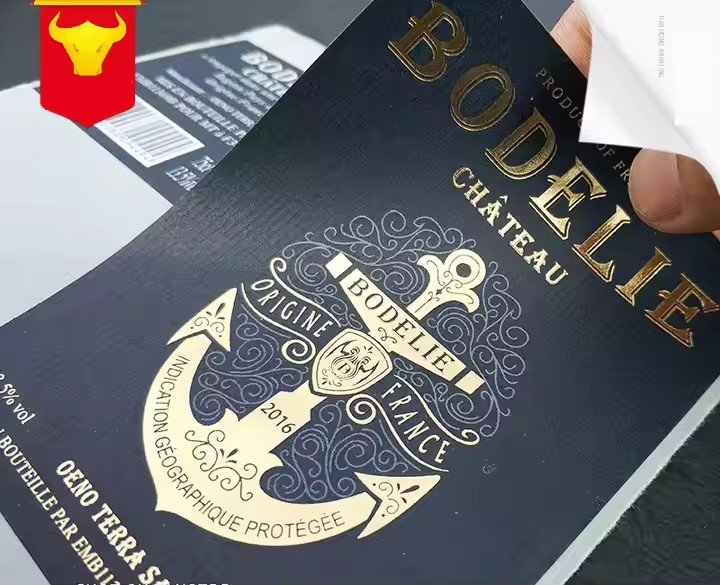

UV printing coatings use UV-cured inks, maintaining stable colors (no fading after 6 months of sun exposure). They are ideal for counter display labels requiring both brand logos and barcodes, while offering special finishes (transparent, matte) to enhance premium appearance.

- Adhesive: Balances Bonding Strength with Jewelry Protection

The adhesive serves as the “bonding bridge” between label and jewelry, with the dual requirement of firm adhesion and clean removal—strong enough to stay during handling and display, yet removable without residue or surface damage (e.g., plating, polish, jade texture).

By adhesion strength:

Low-tack adhesives (≤10N/25mm): Best for smooth surfaces (e.g., polished gold, mirror-finished silver). Leave no residue and prevent plating damage.

Medium-tack adhesives (10–20N/25mm): Suitable for matte jewelry (e.g., brushed platinum, matte K-gold). Provide balanced adhesion and removability, ideal for temporary display labels.

High-tack adhesives (≥20N/25mm): Recommended only for packaging boxes or jewelry accessories (e.g., clasps). Not for direct jewelry contact, as long-term adhesion may damage materials.

By material compatibility:

For silver jewelry, adhesives must be sulfur-free (to prevent tarnishing).

For pearls, coral, and other organic jewelry, solvent-free adhesives are required (to prevent corrosion).

For jade, emerald, and brittle stones, adhesives must retain flexibility (avoiding cracks caused by hardened labels).

II. Key Considerations in Jewelry Barcode Label Material Selection

Beyond material properties, selection must align with the jewelry industry’s unique requirements, evaluated across scanning efficiency, aesthetic harmony, cost control, and compliance. This ensures labels are both functional and consistent with jewelry’s premium positioning.

- Scanning Efficiency: Prioritize Barcode Readability

The primary role of a barcode is fast information retrieval (e.g., product ID, price, material, stock data). Materials should not compromise scanning accuracy.

The substrate color should create high contrast with the barcode. The standard choice is white substrate + black barcode. Avoid light-colored substrates (e.g., off-white, light gray) or transparent substrates, as transparent films can visually blend with jewelry colors (e.g., rose gold, jade green), lowering scanning accuracy.