- Consumer Electronics: Precision Protection and Creative Enhancement

Consumer electronics represent the most important application field for photopolymer stickers. Their high hardness and anti-aging properties perfectly match the usage requirements of smartphones, tablets, and other digital devices, while their unique optical effects provide brands with a key point of visual differentiation.

In the smartphone sector, the use of photopolymer stickers has expanded from basic protection to aesthetic customization. For example, Hangyo Hologram in Korea utilizes Covestro’s Bayfol® HX105 photosensitive photopolymer film to produce 3D holographic stickers integrated into phone backs and protective cases. These stickers deliver vivid colors and wide-angle stereoscopic effects, enhancing product recognition while resisting daily wear, moisture, and temperature changes—maintaining stable performance even under rigorous environmental testing.

In screen protection, photopolymer stickers—featuring high light transmittance (over 90% for some products) and surface hardening—are widely used for phones, tablets, and laptops. They reduce fingerprints, prevent scratches, and maintain touch sensitivity and display clarity. Smartwatches, wireless earbuds, and other compact devices also rely on photopolymer stickers for exterior labeling and interface protection, as their precise die-cutting adapts well to curved surfaces and ensures firm adhesion.

At the electronic component level, photopolymer stickers are also used as insulating labels on circuit boards. Their resistance to high temperatures and chemicals allows labels to remain legible throughout device operation, supporting efficient maintenance.

- Automotive and Transportation: Reliable Performance in Extreme Conditions

The automotive and transportation sectors demand exceptional durability, temperature resistance, and outdoor stability. Photopolymer stickers excel in these environments, making them widely used in vehicle systems and traffic-related signage.

For in-car displays—such as central control screens and dashboards—photopolymer protective films withstand intense sunlight, heat fluctuations, and long-term vibration. They prevent scratches and fingerprints, while low-reflection surface treatments improve visibility under strong light, enhancing driving safety.

For vehicle exteriors and components, photopolymer stickers are used on trim pieces, wheel hub emblems, and engine-bay labels. Their UV resistance and water-resistant properties ensure long-lasting clarity without fading or peeling—even during car washing or high-speed driving.

Electric vehicle battery modules also rely on photopolymer stickers for insulation and safety labeling. These stickers display cell parameters and warning information, adding a protective layer for battery systems.

In traffic signage, some high-grade road signs and parking guidance systems now adopt photopolymer stickers, whose high reflectivity and weather resistance improve nighttime visibility and reduce maintenance frequency.

- Optical and Medical Industries: Precision-Driven Material for Specialized Needs

The optical industry requires extremely high light transmittance and precision. Photopolymer stickers—due to their optical clarity—are widely used for the protection and labeling of optical instruments.

For lenses, temporary protective films for eyeglasses and camera optics are often made of photopolymer material. Their transparency ensures no distortion during optical testing, while their gentle adhesion allows clean removal without residue. Precision equipment such as telescopes and microscopes also use photopolymer stickers for component identification, ensuring accurate assembly.

In the medical device sector, photopolymer stickers serve two core needs: disinfection resistance and high clarity.

Medical monitors and diagnostic displays require protective stickers that withstand frequent cleaning with alcohol or iodine disinfectants.

Surgical instruments use photopolymer labels to mark serial numbers, sterilization dates, and other identifiers. These labels remain intact after high-temperature and high-pressure sterilization, supporting traceable medical safety.

In medical packaging, photopolymer stickers are used as sealing labels for pharmaceuticals and consumables. Their strong adhesion and biocompatibility help prevent contamination while keeping product information easily identifiable.

- Advertising, Decoration, and Fashion: A Tool for Visual Innovation

In advertising and fashion, photopolymer stickers have become a favorite for designers thanks to their high-resolution printing and unique optical effects.

In signage and lightbox advertising, photopolymer overlays improve light uniformity and make graphics appear more vivid. Their scratch-resistant surfaces withstand dust, contact, and outdoor exposure, extending the lifespan of the display. Compared with traditional vinyl stickers, photopolymer materials offer richer gradients, finer details, and stronger visual depth—ideal for premium branding.

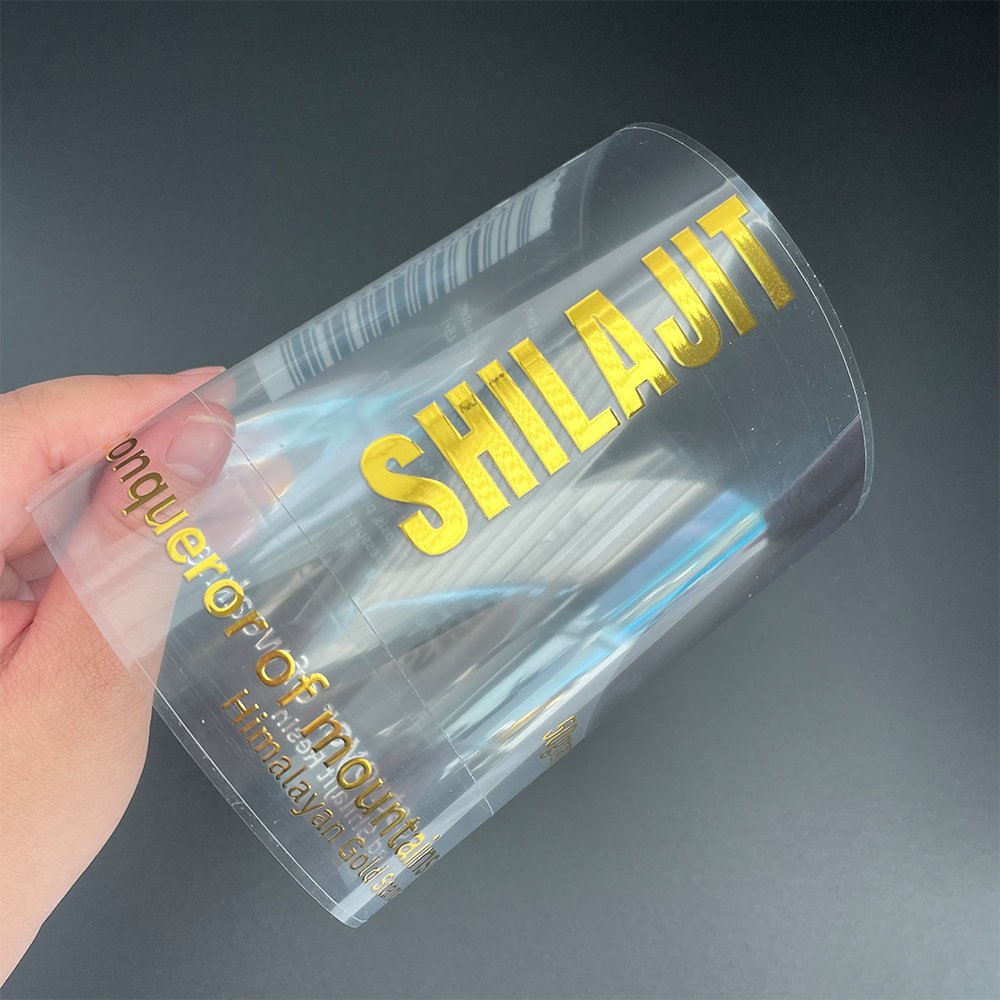

In the fashion sector, photopolymer stickers are used for decorative elements, accessories, limited-edition packaging, and brand identity labels, providing both durability and aesthetic enhancement.