I. Core Selection Principles: Ensuring Alignment Between Material and Premium Positioning

- Prioritizing Texture: Matching the Value of Premium Wines

High-end wines are priced at a premium and target consumers who care deeply about product experience. Label materials must therefore deliver both a refined visual appearance and a sophisticated tactile feel. Avoid low-cost options such as standard coated paper; instead, prioritize materials with natural textures, moderate sheen, or unique tactile effects. The label should feel substantial and well-crafted, echoing the product’s high-end positioning.

- Functional Adaptability: Withstanding Storage and Transportation Conditions

Wines undergo storage (low temperatures, humidity) and transportation (vibration, temperature fluctuations). Label materials must therefore be resistant to scratching, moisture, and abrasion, and should adhere firmly without peeling. As wine bottles typically have curved glass surfaces, materials must offer sufficient flexibility to apply smoothly without bubbles or lifting, maintaining their form over long-term use.

- Compliance & Safety: Meeting Food-Contact Standards

Wine labels come in direct contact with the bottle and may indirectly touch the liquid (e.g., condensation during storage). Materials must comply with international food-contact safety standards such as EU REACH and the U.S. FDA. Avoid inks and adhesives containing heavy metals or harmful solvents to ensure the label is odorless and free from hazardous substance migration, protecting consumer safety.

- Printing Compatibility: Accurately Reproducing Brand Design Details

High-end wine labels often feature complex illustrations, gradients, or premium embellishments like hot stamping or foiling. Materials must offer excellent ink adhesion and color accuracy. Avoid overly smooth or overly absorbent surfaces to ensure crisp graphics, vibrant colors, and flawless execution of special printing techniques that enhance brand sophistication.

II. Main Categories of High-End Label Materials and Suitable Applications

(A) Paper-Based Materials: The Classic Choice for Premium Texture

Paper materials are widely used for high-end wine labels due to their natural texture and warm, elegant appearance. Quality coatings and processing are required to improve durability.

- Specialty Art Paper

Key Features:

Textured surface (e.g., linen, leather, stripe patterns), grammage 150–250 g/m², moderate thickness, delicate tactile feel, and a classic, vintage aesthetic.

Best For:

High-end wines emphasizing heritage, craftsmanship, or a traditional château style, such as Bordeaux classified growths or Burgundy grand cru wines.

Optimization Tips:

Apply matte/ gloss lamination or varnish to enhance moisture and scratch resistance; use water-based inks to reduce odor and meet environmental requirements.

Representative Materials:

Imported tactile papers from Italy, French linen-texture art papers; some premium versions include cotton or wood fibers to enhance depth and tactility.

- Premium Matte Coated Paper

Key Features:

Higher grammage (200–300 g/m²) compared with standard coated paper, matte surface with low reflection, excellent color reproduction, producing a restrained and sophisticated appearance.

Best For:

Modern minimalist designs or wines emphasizing color expression, such as premium New World Cabernet Sauvignon or Chardonnay.

Optimization Tips:

Suitable for spot UV or foil stamping to enhance fine details; eco-friendly pressure-sensitive adhesive ensures strong bonding, clean removal, and protection of the bottle surface.

(B) Film-Based Materials: Durability and Modern Aesthetic Combined

Film materials offer excellent waterproof, scratch-resistant, and abrasion-resistant performance—ideal for wines requiring long-term storage or frequent handling.

- Matte Polyester Film (PET)

Key Features:

Thin and lightweight (25–50 μm), highly flexible for curved bottle surfaces; matte finish with refined texture; waterproof, oil-resistant, abrasion-resistant, and non-yellowing over time.

Best For:

Modern-design, youth-oriented premium wines, or wines transported internationally.

Optimization Tips:

Optional lamination or brushed finish for enhanced tactility; compatible with eco-friendly solvent inks for vibrant, fade-resistant, high-resolution printing.

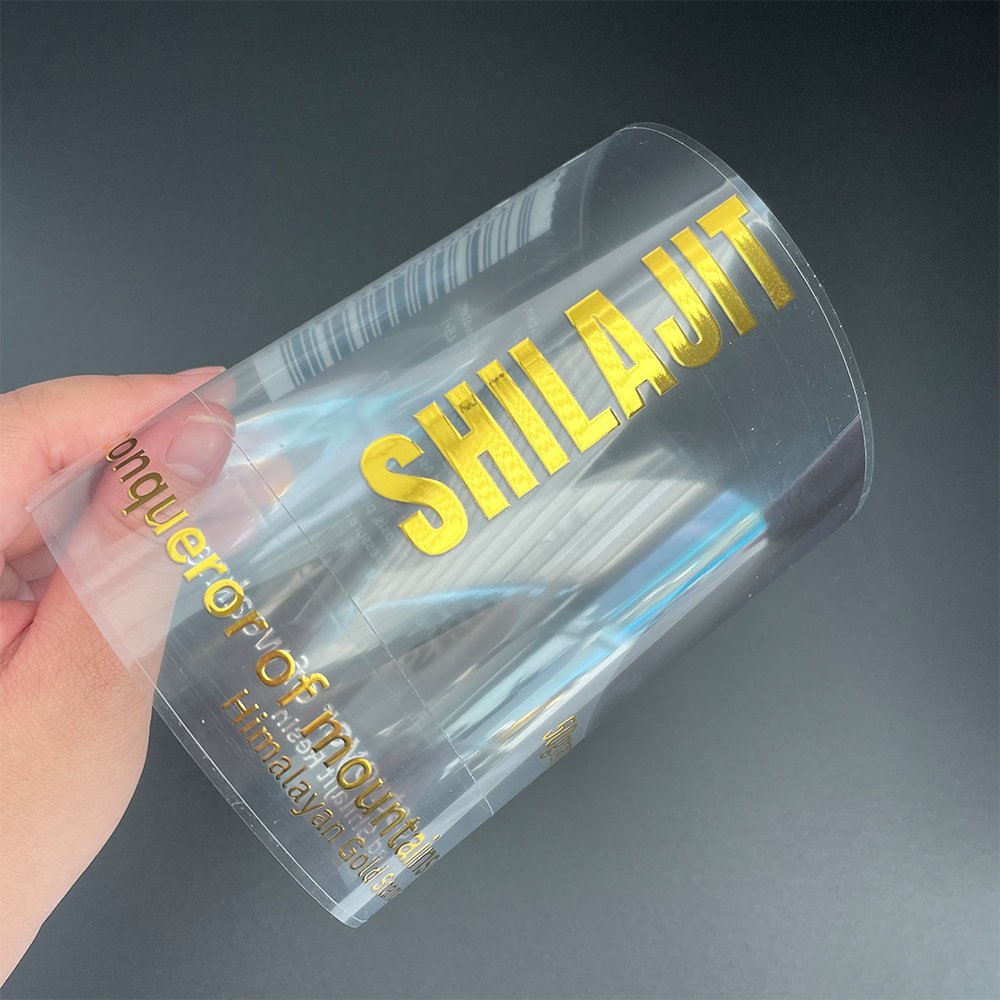

- Polypropylene Film (PP)

Key Features:

Eco-friendly, food-contact safe, soft texture, excellent adhesion; available in matte, frosted, or pearlescent finishes for a translucent, premium look.

Best For:

Environmentally conscious brands, fresh-style white wines, rosé, or organic/biodynamic wines.

Optimization Tips:

Choose BOPP (biaxially oriented PP) for improved stiffness and durability; use solvent-free lamination to minimize chemical residue and enhance safety.

- Synthetic Paper (Paper-Like Film)

Key Features:

Combines paper-like texture with film-level durability; tactile surface similar to paper; waterproof, moisture-resistant, tear-resistant; recyclable and environmentally friendly.

Best For:

High-end wines needing a balance of premium feel and practicality, especially in coastal or humid storage environments.

Optimization Tips:

Works well with foil stamping or embossing for enhanced dimensionality; removable adhesives support bottle recycling and reinforce brand sustainability values.

(C) Specialty Materials: Creating Distinctive and Exclusive Appeal

- Leather-Texture Materials

Key Features:

Made from PU or recycled leather fiber; leather-like grain, soft yet substantial feel, luxurious and highly recognizable.

Best For:

Ultra-premium limited editions or collectible wines, such as commemorative releases or vintage replica editions.