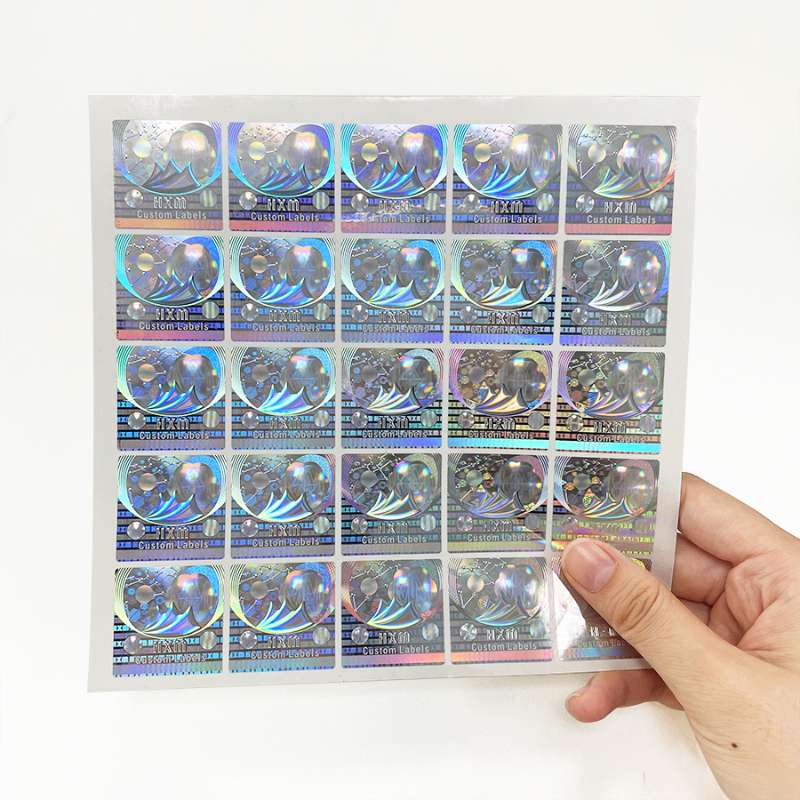

Custom holographic anti-counterfeiting stickers are essential for protecting your brand and products from counterfeiters while providing a visually appealing and distinctive feature that enhances brand recognition.

These stickers utilize holographic elements that are difficult to replicate, making them an effective security measure against counterfeiters.

In this guide, we’ll outline the process of creating custom holographic anti-counterfeiting stickers.

Design Creation:

Define Security Features:

Determine the security features you want to incorporate into the holographic stickers, such as holographic patterns, custom logos, serial numbers, or hidden messages.

These features should be unique to your brand and difficult to replicate.

Design Layout:

Create a visually striking design for your holographic stickers, incorporating holographic elements seamlessly with your brand’s logo, colors, and messaging.

Ensure that the design is aesthetically pleasing while maintaining security features.

Use Specialized Software:

Utilize specialized software or work with a design team experienced in anti-counterfeiting measures to create the design.

This may involve complex holographic patterns or encoding security elements within the design.

Holographic Printing Process:

Choose Printing Method:

Select a printing method capable of producing holographic effects, such as holographic foil stamping, holographic UV printing, or holographic embossing.

Each method offers different levels of customization and security features.

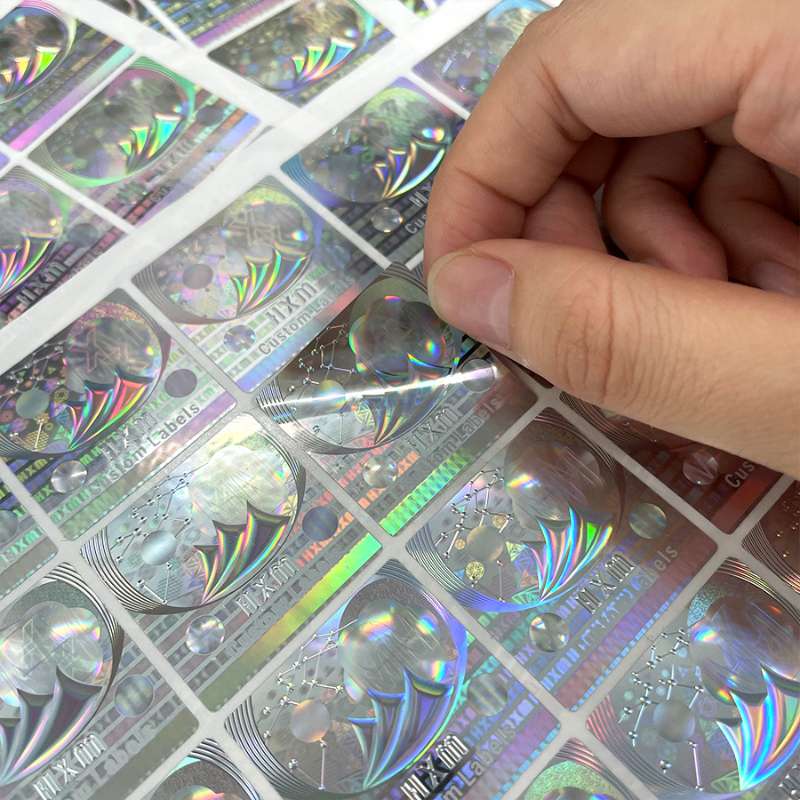

Print Design:

Use high-quality printing techniques to ensure crisp, vibrant holographic effects on your stickers.

Work with a reputable printing company experienced in holographic printing to achieve the desired results.

Test for Authenticity:

Conduct tests to ensure that the holographic effects are accurately reproduced and difficult to replicate.

This may involve using specialized equipment or techniques to verify authenticity.

Incorporate Security Features:

Serialized Numbering:

Include serialized numbering or QR codes on the holographic stickers to track and authenticate each sticker individually.

This allows for traceability and verification of authenticity.

Tamper-Evident Features:

Integrate tamper-evident features into the holographic stickers, such as void patterns or adhesive seals, to indicate if the sticker has been tampered with or removed.

Microtext or Hidden Elements:

Embed microtext or hidden elements within the holographic design that are visible only under magnification or UV light.

These features provide an additional layer of security against counterfeiting.

Quality Assurance:

Inspect Printing Quality:

Thoroughly inspect each holographic sticker for printing defects, color accuracy, and holographic effects.

Remove any defective stickers and replace them with high-quality ones to maintain consistency and security standards.

Test Durability:

Conduct durability tests to ensure that the holographic stickers withstand handling, transportation, and environmental conditions without deteriorating or losing their security features.

5. Distribution and Verification:

Secure Distribution Channels:

Implement secure distribution channels for your holographic stickers to prevent unauthorized access or tampering. Utilize secure packaging and tracking systems to monitor distribution.

Provide Verification Methods:

Educate customers and retailers on how to verify the authenticity of the holographic stickers using serialized numbering,

QR codes, or other authentication methods. Provide access to verification tools or databases to facilitate authentication.

Creating custom holographic anti-counterfeiting stickers requires careful planning, design, and execution.

By incorporating advanced security features and working with experienced printing professionals,

you can create highly secure stickers that protect your brand and products from counterfeiters while enhancing brand recognition and trust.