Label Sizes

When choosing custom label options, wholesalers generally select standard sizes such as square or rectangular labels. These standard sizes are easy to fit various product packaging and may offer cost advantages, as tools like molds are more universal. Standard sizes can save on costs, including communication and production costs between manufacturers and wholesalers, which helps both parties streamline production and product handover. Based on the special shape or packaging design of a product, wholesalers can customize label sizes. For example, for long and narrow products, wholesalers can opt for narrow labels; for curved packaging, they can choose curved labels to better fit the product, enhancing its overall look. Customizing the label size provides diverse options for merchants. For instance, shampoo bottles come in different sizes, so the label size should vary accordingly. Diverse labels help meet the different demands in the market. This customization is flexible and resource-efficient, enabling both parties to quickly reach an agreement.

Label Shapes

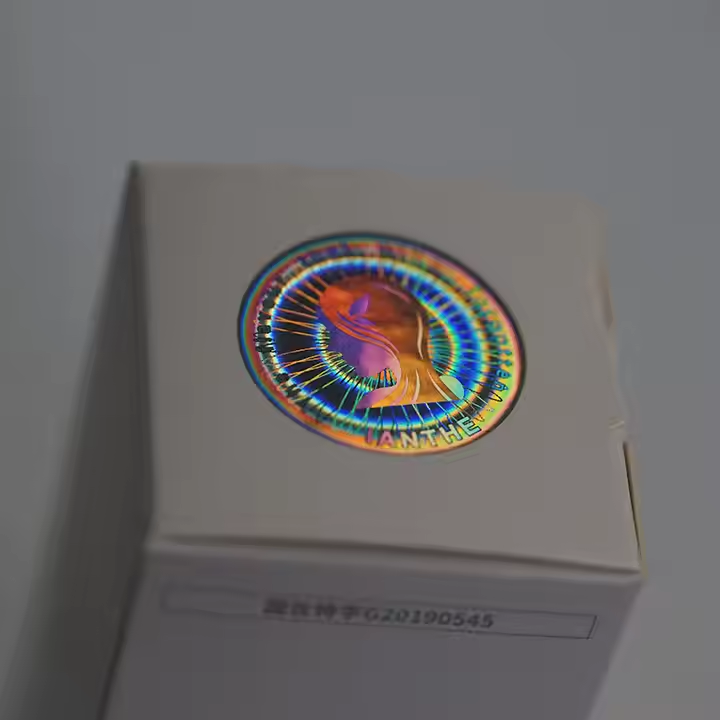

Labels come in various shapes, including the common square and rectangular shapes, as well as round labels. Round labels offer a soft, refined look and are often used for high-end or aesthetically designed products like cosmetics or premium alcoholic beverages. Unique label shapes, such as multi-shape combinations, create interesting and eye-catching designs that attract consumer attention. For example, personalized and unique labels show customers that manufacturers have strong design capabilities, building trust and enabling quick cooperation. Successful companies often showcase their label designs in an internal showroom, which helps establish customer confidence and fosters faster collaboration. If you are looking for customized label packaging, you can contact Huaxinmei Label Industrial Co., Ltd., a company that specializes in label packaging production. With mature experience and a complete supply chain, Huaxinmei can help you customize labels. Contact: WhatsApp +86186680366752.

Some labels are specifically designed in unique shapes to capture attention. For instance, labels can be designed in animal shapes for children’s products, plant shapes for gardening products, or even product shapes (like a car-shaped label for automotive parts). If you want to design a label based on your product’s characteristics, for example, a chocolate candy product could feature a candy-shaped label. This design allows consumers to instantly recognize the product, leading to a quicker decision and preference.

Material Choices

There are many material options depending on your needs. If your product is in the mid-range market and aims for high sales volume with a low margin, you might opt for standard paper materials as they are cost-effective and forgiving. For example, cosmetic products targeting a general market can use ordinary paper packaging like coated paper, which is suitable for colorful designs and detailed text. It is affordable and commonly used for everyday product labels such as stationery or regular food items.

Other products use kraft paper, which is strong, durable, and tear-resistant, commonly used for bags, envelopes, notebooks, record covers, files, and sandpaper. Kraft paper has a natural, rustic feel and is perfect for handmade products, organic foods, or vintage-style home goods, conveying an earthy, eco-friendly vibe. If your product is heavy, such as ceramics, kraft paper could be used for the outer packaging or as an inner layer.

Thermal paper is suitable for products requiring thermal printing, like logistics labels or price tags, known for its fast printing speed and convenience.

Plastic packaging materials are also widely used. There are various types of plastic materials, such as polyester film, which is durable, water-resistant, chemically resistant, and weather-resistant. It’s ideal for products that need long-term storage or are used in harsh environments, such as electronic products or outdoor gear. Polyvinyl chloride (PVC) is flexible and can be used for curved or elastic labels, like those on cables or toys, although its environmental impact is a concern in some applications. Polypropylene is moisture-resistant and often used for products sensitive to humidity, such as bathroom items or water sports equipment.

Special materials can be used for unique products. For example, synthetic paper combines the properties of both plastic and paper, making it tear-resistant and durable, suitable for outdoor advertising or long-lasting product labels. Laser materials create eye-catching effects, often used for luxury products like cosmetics, gifts, or alcohol, enhancing the product’s perceived value.

Printing Methods

Traditional printing methods include offset printing, which offers high-quality results and accurate color reproduction, making it suitable for printing colorful and complex labels, like food or beverage packaging. Offset printing typically requires a minimum print run, making it ideal for large orders.

Other printing techniques include flexography and gravure. Flexographic printing creates a raised effect for text or images, while gravure printing produces an engraved effect. Both methods add texture and are often used for high-end product labels, like those on luxury leather goods or premium wines.

As technology advances, many companies now use digital printing, such as inkjet printing, which allows for personalized, small-batch label printing. This method is perfect for customizing labels with different batch numbers or names, offering flexibility for small orders. Laser printing is also popular, providing high precision and clear prints on various materials, making it ideal for products that require detailed and accurate labels .