Data Management and Tracking Technologies

Accurate management of product information: Manufacturers can efficiently manage and store various data related to labels, such as product specifications, production batches, production dates, and customer order numbers, using data management software. This ensures the accuracy and completeness of product information, providing strong support for production, sales, and quality traceability. By managing the production of custom labels with detailed information, manufacturers can trace batches, estimate production timelines, and improve efficiency, allowing them to take on more orders and increase profits.

Real-time Tracking and Monitoring Support

By integrating IoT technologies, such as embedding sensors or using RFID and NFC chips in labels, real-time tracking and monitoring of products are possible. For example, in warehouse management, RFID-tagged items can be automatically recognized and tracked, ensuring real-time updates of inventory and improving stock management. Additionally, real-time production monitoring helps quickly identify and correct any issues, maintaining high production quality.

Printing Technologies

Meeting personalized customization needs: The development of digital printing technology has made custom label production more flexible and efficient. Digital printing eliminates the need for plates, allowing manufacturers to quickly print personalized labels with specific designs, patterns, and colors to meet small-batch, diverse customization needs while reducing production costs and lead times. This enhances efficiency, helping factories meet delivery deadlines and boost profits.

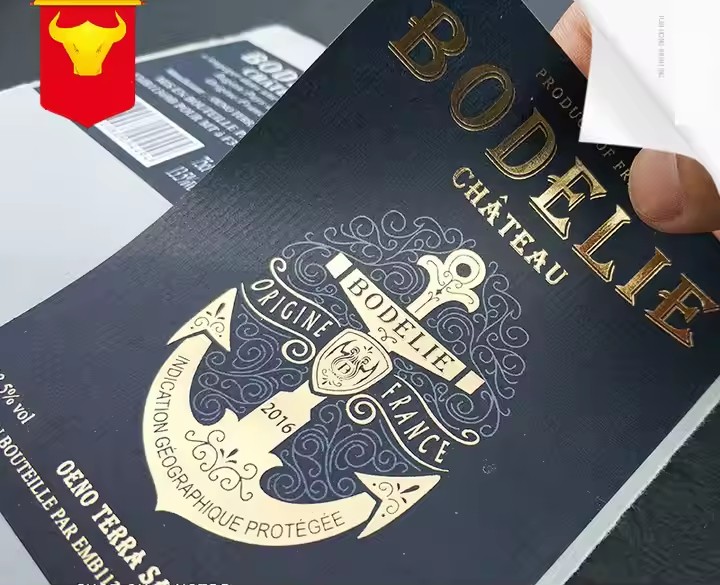

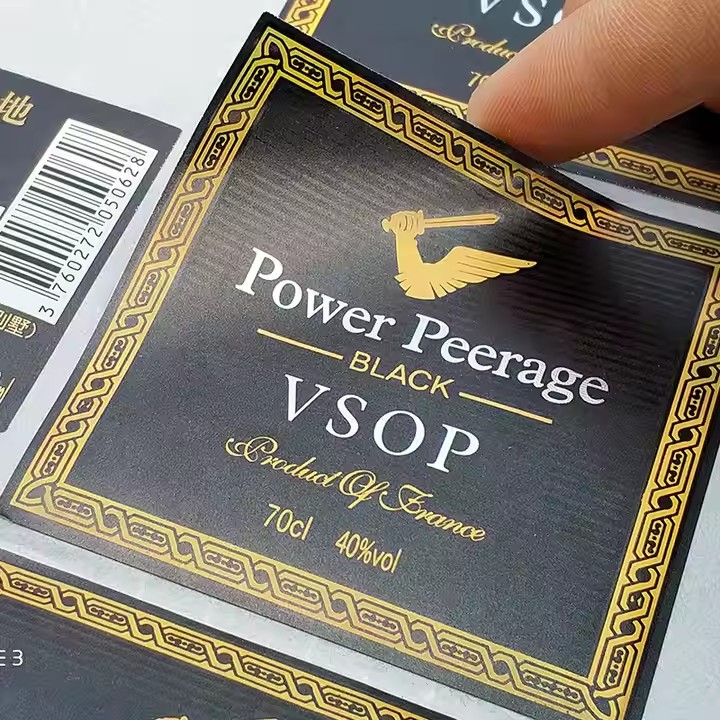

Improving Label Quality and Durability

Advanced printing equipment and materials, such as high-precision inkjet and laser printers, along with premium inks and papers, ensure high-quality, durable labels. These labels resist wear, fading, and moisture, extending their lifespan. High-quality materials are essential for producing premium labels, particularly for products with high aesthetic demands, such as trendy toy packaging, which requires striking and eye-catching materials.

Automation Technologies

Improving production efficiency: Automated labeling machines and printers can perform tasks such as printing, cutting, and attaching labels quickly and accurately, significantly boosting efficiency and reducing manual errors. This is especially beneficial for large-scale production. Efficiency can be improved by utilizing advanced machinery and building effective management teams to optimize the entire production process.

Enhancing Production Consistency

Automated systems ensure that labels are produced consistently to high standards, minimizing quality issues and waste. This consistency is vital for personalized label packaging, as customers expect uniformity and high quality in their customized products. Strengthening team collaboration and introducing incentive mechanisms can further enhance overall production consistency.

Identification and Anti-counterfeiting Technologies

Facilitating product identification and classification: Barcode and QR code technologies are widely used in custom labels, enabling easier product identification, classification, and management. Scanning barcodes or QR codes helps workers quickly retrieve product information, automating production, warehousing, and logistics, which increases work efficiency and accuracy. These technologies also enhance customer experience by providing instant access to product-related information and promotions, particularly useful for seasonal or holiday campaigns.