Design Stage

Understand Customer Needs: Clearly define the type, positioning, target audience of the gift, as well as the special requirements of the customer for the packaging box, such as style, color, theme, etc., in order to design a solution that meets the customer’s expectations. The style required by the customer is very important. Match the style according to the style known by the customer, and produce the product after knowing the style.

Consider Product Characteristics: Design according to the characteristics of the gift, such as shape, size, weight, texture, etc., to ensure that the packaging box can provide appropriate protection and display effects. For example, fragile items require a more robust structure and cushioning design; high-end gifts need to reflect a sense of quality and uniqueness. For instance, if the customer requests a high-quality gift box design, choose high-quality products for design according to the customer’s requirements. Considering product characteristics is the foundation, because only by taking into account the product’s tone and ensuring that the designed gift box matches the product can it be more favored by consumers.

Design Rationality: Ensure that the structural design of the packaging box is convenient for production, assembly, and packaging, and also consider cost factors. Avoid overly complex designs that lead to high production difficulty or costs. In addition, consider the convenience of transportation and storage, and try to design a foldable or compact structure to save space and transportation costs. The design should consider the rationality of the design, such as the size, shape of the design, and whether the product can be placed in the designed size.

Comply with Relevant Regulations: The design content should comply with laws and regulations to avoid issues such as infringement and false promotion. At the same time, pay attention to following environmental protection regulations and try to use environmentally friendly materials and recyclable designs. Of course, when designing, relevant regulations need to be followed, because it is not allowed to violate relevant regulations, so as to avoid waste of production materials.

Material Selection

Quality and Safety: Select materials with good quality and high strength to ensure that the packaging box can withstand the weight of the gift and the bumps during transportation. At the same time, the materials should meet relevant standards for food safety, environmental protection, etc. Especially for gift packaging that comes into direct contact with the human body, such as food and cosmetics, ensure that the materials are non-toxic and harmless.

Compatibility: Select appropriate materials according to the characteristics of the gift and the design requirements of the packaging box. For example, paper materials are suitable for most gifts, and they have advantages such as low cost and good printing performance; wooden materials are suitable for high-end gifts with cultural connotations and can reflect a sense of texture and grade; plastic materials have high transparency and are suitable for display gifts, but pay attention to their environmental friendliness.

Consider Cost: On the premise of meeting quality and design requirements, try to select materials with reasonable costs to control production costs. Long-term cooperative relationships with suppliers and bulk purchasing can be adopted to reduce material costs.

Printing Process

Color Accuracy: Strictly print according to the color requirements of the design draft to ensure that the printed color is consistent with the design draft. Before printing, conduct color proofing and sampling, and carry out formal printing after obtaining customer confirmation. At the same time, pay attention to the color consistency between different printing batches.

Printing Quality: Ensure that the printed pattern is clear and delicate, without defects such as blurring, ghosting, and missing printing. Select appropriate printing processes and equipment, and adjust the printing parameters according to the characteristics of the materials to obtain the best printing effect. In addition, pay attention to the adhesion and abrasion resistance of the ink to ensure that the printed pattern will not fade or peel off easily during the use of the packaging box.

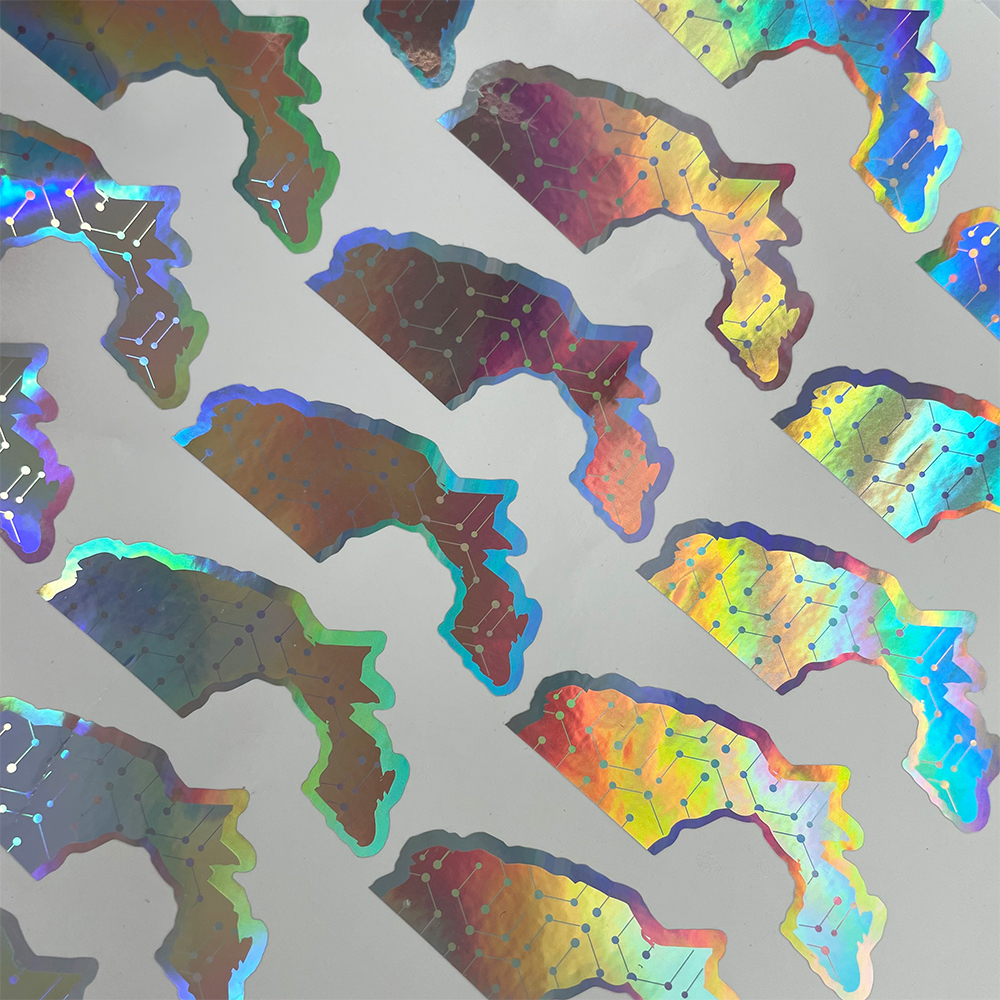

Surface Treatment: Carry out appropriate surface treatments according to the design requirements of the packaging box, such as lamination, glazing, hot stamping, embossing, etc. These treatments can not only improve the aesthetics and texture of the packaging box but also enhance its abrasion resistance and water resistance. However, pay attention to the compatibility between the surface treatment process and the printing ink and materials to avoid problems such as bubbling and delamination.

Processing and Molding

Cutting and Die-cutting Precision: Perform precise cutting and die-cutting according to the design size to ensure that the various parts of the packaging box are accurate in size and have neat edges. Regularly maintain and calibrate the cutting and die-cutting equipment to ensure precision. At the same time, pay attention to avoiding burrs or debris generated during the cutting process, so as not to affect the appearance and use of the packaging box.

Folding and Gluing Quality: The folding parts should have clear and straight creases to ensure that the packaging box can be folded smoothly. The gluing parts should be firmly glued to avoid problems such as opening and delamination. Select appropriate glue, and adjust the amount of glue and drying time according to the materials and environmental conditions to ensure the gluing quality.

Assembly Precision: For packaging boxes with multiple components, ensure the assembly precision of each component to ensure the overall structural stability and tightness of the packaging box. For example, the fit between the box cover and the box body should be tight, and the drawer of the drawer-type packaging box should be smooth.

Quality Inspection

Appearance Inspection: Check whether the appearance of the packaging box meets the design requirements, including whether the color, pattern, and text are correct, and whether there are printing defects, surface stains, scratches, etc. At the same time, check whether the overall shape of the packaging box is regular, and whether there are problems such as deformation and twisting.

Size Precision Inspection: Measure whether the various dimensions of the packaging box meet the design specifications, including length, width, height, inner diameter, outer diameter, etc. The size deviation should be controlled within the allowable range to ensure that the packaging box can fit the gift.

Structural Strength Test: Conduct structural strength tests on the packaging box, such as compression tests, drop tests, opening and closing tests, etc., to check whether it can withstand a certain amount of external force during transportation and use and protect the gift from damage. For some packaging boxes with special requirements, corresponding special tests, such as waterproof tests and moisture-proof tests, are also required.

Function Inspection: Check whether the various functions of the packaging box are normal, such as whether the flip cover is flexible, whether the zipper is smooth, and whether the handle is firm. Ensure that the packaging box is convenient and fast to use and will not have functional obstacles.