- In-Depth Analysis of Bottle Shape: Laying the Foundation for a Perfect Fit

The shape of the bottle is the primary basis for label design. Different bottle shapes require different design and production approaches. Common bottle shapes include cylindrical, square, and irregular forms, each needing a tailored design strategy.

(1) Cylindrical Bottles

Cylindrical bottles are the most common type, with evenly curved surfaces that make label application relatively easy. However, precise measurement of the bottle’s circumference, diameter, and curvature is essential. Generally, the label length should be slightly shorter than the bottle’s circumference, leaving a small overlap for secure adhesion. For instance, bottled water labels typically leave a 3–5 mm overlap on the edge, using adhesive or pressure-sensitive labels for a tight seal.

To prevent wrinkles or bubbles on curved surfaces, the label material should match the bottle’s curvature in flexibility and stretchability. Materials like PET pressure-sensitive labels are ideal as they ensure a smooth finish and excellent waterproof performance.

(2) Square Bottles

Square bottles feature distinct edges and corners, requiring special attention during label application. A segmented design approach can be used—dividing the label into multiple panels, each corresponding to a flat surface of the bottle. At the corners, slight cutting or folding treatments help ensure a seamless transition.

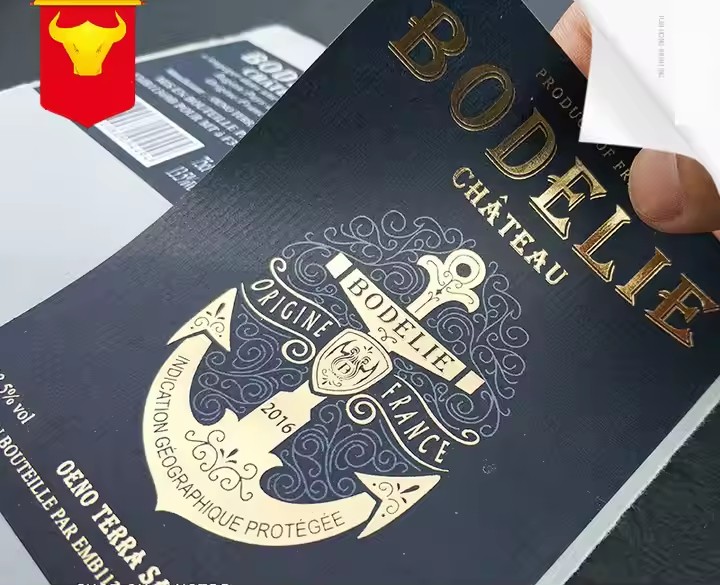

For example, square perfume bottles may use chamfered or rounded corner cuts to reduce harsh transitions. Additionally, embossing, foil stamping, or other finishing techniques can be used to highlight elements like the logo or product name, enhancing the three-dimensional effect and visual harmony with the bottle. Square bottles generally require more label material due to their surface geometry.

(3) Irregular Bottles

Irregular bottles, while visually striking, pose greater challenges for label fitting due to their asymmetrical curves, indentations, or custom shapes. These require personalized solutions based on the specific bottle design.

For example, artfully shaped liquor bottles may have raised textures or sunken patterns, necessitating 3D modeling to precisely capture surface contours. Digital printing and die-cutting can then produce a label that conforms exactly to the bottle. Stretchable label materials may also be used for complex surfaces to ensure a smooth, snug application.

- Choosing the Right Label Material for Optimal Adhesion

The material properties of the label are crucial to how well it adheres to the bottle. Each material comes with different physical attributes—such as flexibility, water resistance, and durability—that must be selected based on the bottle’s material, usage conditions, and design needs.

(1) Paper Labels

Paper labels are among the most commonly used due to their low cost and excellent printability. However, standard paper lacks flexibility and water resistance, making it prone to deformation or peeling.

To improve this, specially treated paper materials like laminated coated paper or synthetic paper can be used. Laminated paper has a smooth surface with enhanced water and abrasion resistance, ideal for beverage and food bottles. Synthetic paper combines the benefits of paper and plastic, offering strong tear resistance and moisture protection—suitable for cosmetics and personal care products that require durability.

(2) Plastic Labels

Plastic labels—such as PET or PVC—are known for their superior flexibility, waterproofing, and chemical resistance. They are suitable for complex bottle shapes.

PET labels are highly transparent and smooth, perfect for premium packaging like luxury spirits or perfumes, and enhance product perception. PVC labels are more elastic and adaptable, ideal for irregular bottle shapes or bottles requiring stretchable labels—such as sports water bottles or children’s product containers. Additionally, screen printing or thermal transfer techniques can create vivid colors and special effects to boost visual appeal.

(3) Metal Labels

Metal labels, such as aluminum foil labels, offer a distinctive metallic texture and a premium look. They are often used in high-end spirits or gift packaging.

Due to their rigidity, metal labels require specialized equipment and processes. Typically, foil sheets are die-cut or embossed, then affixed using heat or adhesive. During design, the extensibility and shrinkage of metal materials must be considered, leaving appropriate processing tolerances to avoid edge curling or wrinkling after application.

- Using Finishing Techniques to Improve Fit and Quality

Beyond material selection, label manufacturing techniques also play a vital role in how well a label fits and looks on the bottle. Proper finishing not only ensures durability but also enhances the visual and tactile quality of the label.

(1) Printing Techniques

Different printing methods yield different visual and tactile effects, influencing the label’s performance.

Offset printing is suitable for large-scale production, offering high precision and color fidelity, ideal for standard paper labels.

Screen printing creates a thicker ink layer, delivering texture and a 3D effect, suitable for matte or embossed finishes.

Digital printing is fast and flexible, requiring no plates. It enables personalization and is particularly well-suited for small-batch, customized bottles like gift editions or limited-edition products.