Design Innovations

In the early stages of label design, after discussions between manufacturers and clients, unique structural designs can be implemented. Some manufacturers create labels with special structures, such as three-dimensional labels or labels that can be extended or folded. Three-dimensional labels stand out from the product packaging, attracting consumers’ attention, while extendable or foldable labels can increase the display area, allowing more information to be conveyed. For example, some cosmetic labels are designed to unfold, revealing detailed usage instructions and ingredient information when opened. Additionally, some alcoholic beverage labels feature three-dimensional designs that emphasize a high-end, sophisticated brand image. Labels can also be customized into unique shapes, allowing for personalized innovations that make it easier for consumers to remember the product. Labels are no longer limited to traditional rectangular or circular shapes; manufacturers can create unique shapes such as hearts, animals, or silhouettes of the products themselves based on product characteristics, brand identity, or customer needs. This personalized shape design helps products stand out among competitors and enhances brand recognition. The uniqueness of personalized labels is crucial, as only distinctive labels can be easily remembered by consumers, thereby strengthening market competitiveness.

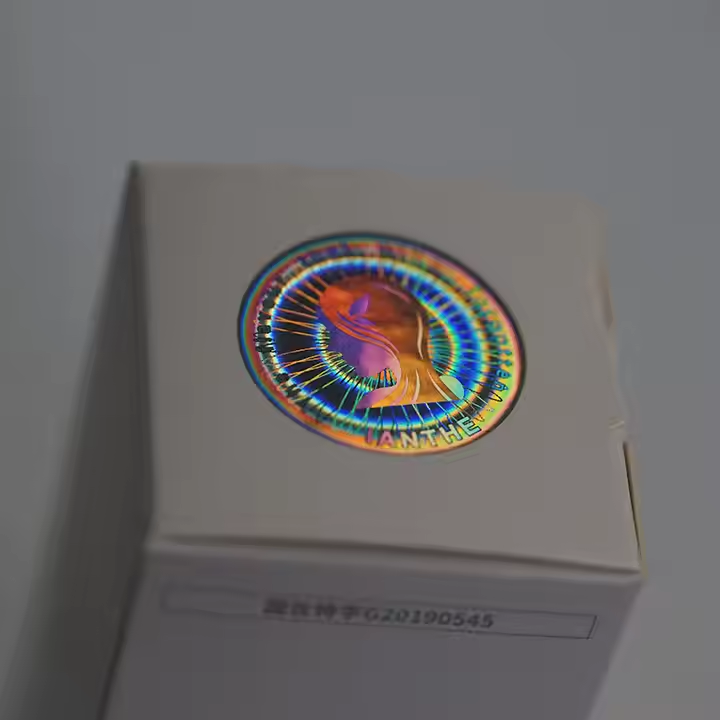

Functional Innovations

Many products include anti-counterfeiting labels, and with market demand for such features, label manufacturers must innovate in this area. Enhanced anti-counterfeiting measures can incorporate advanced technologies, such as special inks, hidden patterns, laser security features, and QR codes. Consumers can verify the authenticity of products by scanning QR codes or observing hidden anti-counterfeiting patterns under specific lighting, ensuring product quality and safety. These anti-counterfeiting technologies are often used on labels for high-end products like alcohol and cosmetics. Additionally, the presence of QR codes allows for further innovation by utilizing IoT technology and big data to add traceability functions to labels. By scanning QR codes or other identifiers on the labels, consumers can access detailed information about product manufacturing, source materials, production batches, and transportation processes, thereby enhancing trust in the product. When consumers are better informed about a product, they are more likely to make a purchase, stimulating their desire to buy.

Material Innovations

In recent years, with the growing awareness of environmental protection, consumers are increasingly focusing on sustainable packaging. Manufacturers are now more frequently using eco-friendly materials for labels, such as biodegradable papers, bio-based plastics, and water-based inks. These materials can decompose more quickly in the natural environment, reducing pollution and meeting consumers’ demand for environmentally friendly products. Eco-friendly label packaging satisfies both the need for minimal environmental impact and the consumer’s preference for sustainable options, highlighting the many benefits of innovation in the label market.

Printing Process Innovations

Utilizing multi-color and high-precision printing techniques can achieve richer, more vibrant color effects, making label patterns and text clearer and more realistic. High-precision printing accurately presents complex design details, enhancing the overall quality and visual appeal of the labels. Good multi-color printing aligns with customer needs and effectively attracts consumer attention. Additionally, to innovate in custom labels, manufacturers can use special inks beyond standard options, such as fluorescent inks, color-changing inks, and scented inks. Fluorescent inks glow in dark environments, increasing visibility and attracting public interest. Color-changing inks alter their color under different temperatures or lighting conditions, adding a playful and anti-counterfeiting element to the labels. Scented inks can emit specific fragrances, capturing consumer attention and creating intrigue—consumers may wonder how a label can smell, extending their engagement with the product and stimulating purchases. Furthermore, innovations in custom labels can include 3D printing, which creates a three-dimensional effect on labels, making the designs more vivid and providing consumers with a fresh visual experience. The effect of 3D printing is significantly different from standard methods; it adds depth and realism, making the product more engaging. For example, during the Qixi Festival, some cosmetic brands may use 3D designs on their packaging, as these gifts are often presented to loved ones, creating a surprising and eye-catching effect.