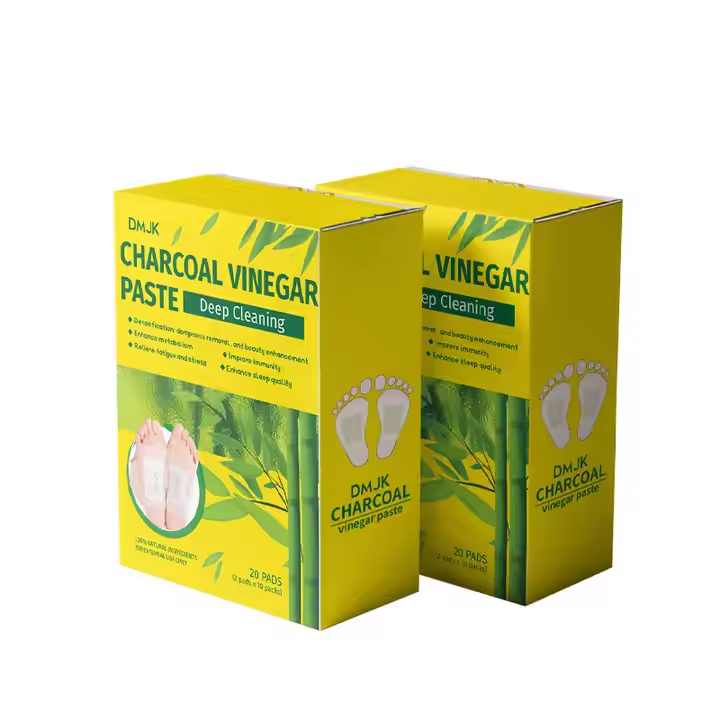

There are many suitable materials for factory-customized labels, depending on your specific needs. Different industries, label types, and packaging requirements result in varying demands. For example, if your company is in the skincare industry, hot stamping is a very suitable choice, as cosmetics are a daily use product aimed at making women feel more beautiful and confident. Labels in this category are usually bright, with primary colors like green, white, and sky blue, creating a clean, bright, and healing feeling. If your company produces color cosmetics, high-brightness hot foil stamping in gold and silver is necessary because the essence of color cosmetics is vibrancy and beauty. Thus, the external label needs to be eye-catching, with designs in red and gold being very appropriate. If your industry is food, you can opt for high-saturation labels to stimulate people’s desire to eat the food, so be bold with colors in your label design. The purpose of label packaging design is to attract consumer purchases, and products circulating in the market need to stand out; otherwise, they risk being eliminated by competing products.

There is no best label packaging; only suitable label packaging exists.

For factories, there is no “best” material; any material can be considered the best depending on how it aligns with the product. Look at established brands in the market and learn how they succeed. Additionally, analyze why others’ label products excel—is it their design, their striking packaging, or the alignment of the packaging with the company’s product tone? Learn from leading companies and adopt advanced technologies and design concepts to create good product label packaging. Material usage must be based on factors like brand identity, quality, tone, and brand recognition, which are crucial for establishing brand awareness and ensuring the product can compete in the market. This is somewhat like how celebrities create their public personas; for products, what is their persona? This persona should be reflected in the product’s label and packaging, highlighting and amplifying the product’s strengths and characteristics. A product’s market presence relies heavily on its labels and packaging being memorable to consumers.

Label packaging is the external manifestation of a product.

Label packaging is akin to clothing for a person; a product’s usage and advantages cannot be extensively presented on the product itself, relying instead on external labels to convey the product’s concept and meet consumer demands. Consumers need to recognize that this product is suitable for them and for the majority of consumers. Label packaging should maximize visibility, showcasing product characteristics and influence. When designing label packaging, consider factors such as product size, quantity, material choice, and whether to add enhancements to make the product more attractive and eye-catching. For example, if you need one million labels, you can negotiate with manufacturers for a better price. You also need to customize the shape of your packaging; different shapes require different material areas, such as square versus rectangular boxes, and material types may vary as well. Should you use paper or plastic packaging? If using paper, should it be kraft paper or A4 paper? Glassine or parchment paper? Different paper types suit different industries. Should you innovate before major holidays, or stick to tradition? If you wish to innovate, be prepared to invest significantly in product development, which comes with corresponding economic costs. High investment in innovative product design can yield high returns if the packaging helps the product succeed. Conversely, if the product fails to gain market traction due to unfavorable conditions, the funds invested in innovation may go to waste. All these factors must be considered in label packaging design. If you can bear the risks and potential rewards of financial investment, then invest decisively in innovation; otherwise, stick to traditional methods.

Choosing materials for label packaging requires considering cost-effectiveness.

Label packaging is diverse and varies widely in the market, so you must learn to select and discern wisely. Small and medium enterprises should consider the price of label packaging, materials, the need for fine processing, and the quantity of labels required. Ordering larger quantities can reduce costs but may also lead to inventory issues, which in turn can result in increased rent expenses. Carefully budget and address all potential issues. When facing similar competitors, analyze what they do well to gain market favor. Always observe your competitors’ successes. If your label packaging fails to capture the market, analyze the reasons behind the failure to avoid repeating mistakes in the future. Additionally, keep an eye on current trends; integrating label packaging with contemporary trends can help you capture market interest. Product labels should also reflect traditional cultures of each country, as cultural identities are deeply ingrained. Incorporating traditional culture into label packaging awakens the cultural instincts in consumers, facilitating their purchasing decisions.