In label and packaging design, metallic effects are often the first element to catch a consumer’s eye.

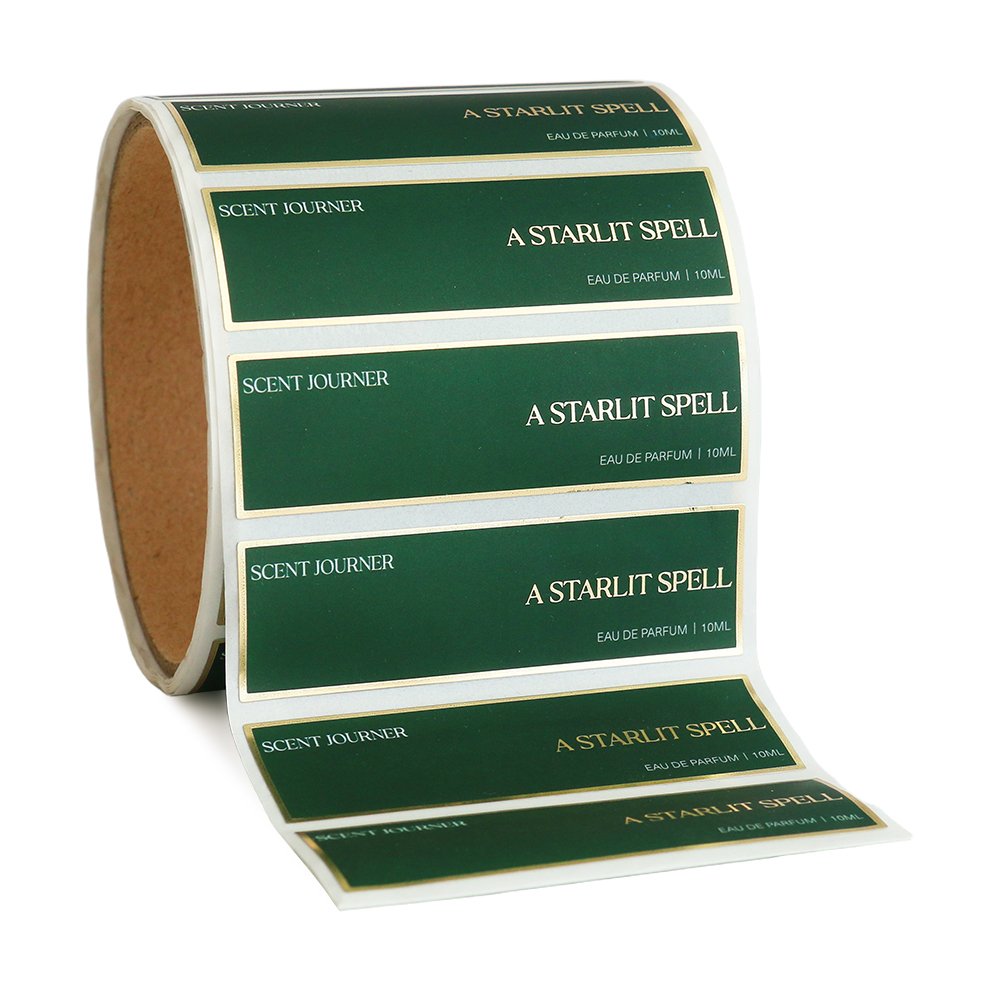

Whether it’s a shimmering perfume bottle label or metallic lettering on premium health products,

foil stamping instantly elevates a brand’s sense of “premium quality.”

But when choosing, many clients ask: “What’s the real difference between hot stamping and cold foiling?

Which is better for my product?”

Let’s break down their differences and applications in a clear, straightforward way.

I. Key Differences Between Hot Stamping & Cold Foiling

- Hot Foil Stamping: Uses a heated metal die to press the metallic layer from a foil roll onto the material surface. It relies on heat and pressure for adhesion.

- Cold Foiling: Requires no heat. It uses UV adhesive and standard printing equipment to transfer the metallic foil, which is then cured and fixed by UV light.

1. Material Compatibility – A Counterintuitive Difference

This is a crucial differentiator, and it’s often the opposite of what people expect:

- Hot Stamping: Offers broader material adaptability. It works well on textured, coated, or even slightly rough papers. Importantly, it can be combined with embossing in a single pass, creating raised, sculpted metallic effects – something cold foiling cannot achieve.

- Cold Foiling: Requires a perfectly smooth, flat surface (like gloss films or coated papers) for flawless foil transfer and adhesion.

2. Visual & Tactile Appearance

- Hot Stamping produces a thicker metallic layer with higher gloss, a distinct 3D depth, and an engraved, luxurious feel. It offers superior visual and tactile impact, making it a favorite for wine and high-end perfume labels. However, due to the heat and pressure involved, it struggles with extremely fine lines and very small text.

- Cold Foiling creates a smoother, flatter finish, ideal for intricate patterns, fine details, and gradient designs. It also allows for overprinting with inks, enabling creative color effects. This results in a more refined, modern look, popular for cosmetics, beverages, and personal care products.

Both processes offer a wide range of metallic colors and mirror effects.

II. Cost Differences & Production Time

Cost Analysis:

- Hot Stamping: Higher initial investment. Specialized stamping machines and custom metal dies are expensive. However, for long runs and high volumes, its efficiency and stability can lower the per-unit cost, making it more economical at scale.

- Cold Foiling: Lower startup costs. It integrates directly into the printing press, eliminating the need for a dedicated stamping machine and using cheaper standard printing plates. However, foil waste can be higher, increasing material costs. It’s highly cost-effective for short to medium runs.

Turnaround Time:

- Hot Stamping: May require a separate, dedicated production step and more complex setup, often leading to slightly longer lead times.

- Cold Foiling: Faster. Combining printing and foiling into a single, compact process makes it ideal for orders with tight deadlines.

III. Metalized Label Materials: A Practical Alternative

Beyond traditional foiling, another way to achieve a metallic look is through Metalized Films.

These materials come with a built-in metallic lustre. Effects are created using transparent inks, matte varnishes, or selective printing.

Advantages include:

- No foil required; ideal for large-area metallic effects.

- Supports full-color printing while offering better water and abrasion resistance.

- Cost-effective, especially for high-volume industries like beverages, health products, and cleaning supplies.

Need free printed samples of hot stamping, cold foiling, or metalized labels?

Contact us now to discuss your project and receive customized samples!