Industrial Manufacturing: The Core Medium for Traceability and Compliance

In industrial production, aluminium labels serve as essential carriers for product identification, quality traceability, and safety warnings. Their stability ensures long-term usability in complex production environments.

Machinery & Equipment Manufacturing

Permanent identification needs: Machine tools, engines, and heavy machinery can last for decades, yet traditional paper or plastic labels are easily damaged by oil, high heat, or friction. Aluminium labels, treated by anodizing to create a hardened surface, can withstand temperature fluctuations from –50 °C to 150 °C and resist chemical corrosion, ensuring information remains legible over time. For example, aluminium labels on automotive engine blocks display model numbers, serial numbers, and emission standards that remain readable despite exposure to heat and oil.

Traceability system integration: In precision manufacturing (e.g. aerospace, medical devices), aluminium labels are often paired with laser marking technology to etch unique codes (QR codes, serial numbers) onto the surface. Scanning these codes allows full lifecycle tracking—from raw material origin to production processes and quality inspection records. This tamper-proof marking method is key to meeting industry compliance requirements.

Electronics & Electrical Appliances

Miniaturised marking needs: Electronic components (chips, resistors, connectors) are small and must retain their labels during soldering and high-heat processes. Aluminium labels, which can be made as thin as 0.1 mm, offer high-temperature resistance and are ideal for such scenarios. For example, aluminium tags on smartphone circuit boards clearly record model and specification data without deforming during soldering.

Safety certification markings: Electrical products (e.g. refrigerators, air conditioners) require permanent energy-efficiency labels and safety marks (CE, UL). Fixed via adhesive or riveting, aluminium labels can resist everyday wear, moisture, and abrasion, ensuring consumers can always access key information.

Construction & Engineering: Dual Value in Durability and Functionality

In the built environment, labels must withstand weathering, UV exposure, and temperature shifts. Aluminium’s weather resistance and structural strength make it a top choice.

Architectural Signage Systems

Public space wayfinding: In malls, airports, and office buildings, aluminium directional signs (floor indexes, emergency exits) combine functionality with aesthetics. Through anodized colouring, labels can retain a metallic finish or custom tones to match architectural styles, while UV resistance prevents fading and reduces replacement costs.

Equipment & pipeline identification: Internal facilities—water pipes, cables, air ducts—require clear markings for purpose, flow direction, and pressure ratings. Aluminium labels, fixed with ties or magnets, withstand damp and dusty conditions, ideal for basements or equipment rooms.

Engineering & Building Materials

Material traceability: Steel rebar, aluminium profiles, and glass are often tagged at production with aluminium labels listing batch numbers, specifications, and mechanical properties for quality verification on site. For example, steel rebar labels must match test certificates to ensure compliance with design standards.

Project acceptance tags: In large projects such as bridges or tunnels, critical structural components (steel members, embedded parts) are marked with aluminium inspection tags recording installation date, inspector name, and load ratings, serving as permanent quality records.

Consumer Goods & Packaging: A Medium for Brand Value and Premium Appeal

Aluminium’s metallic finish and customisation potential make it a go-to for enhancing brand image, particularly for mid- to high-end products.

Luxury & Premium Goods

Brand identity reinforcement: Jewellery, watches, and luxury leather goods often feature aluminium nameplates bearing engraved or embossed brand logos, echoing the product’s premium positioning. For example, aluminium back-plate tags on luxury watches both display brand information and add a refined tactile quality.

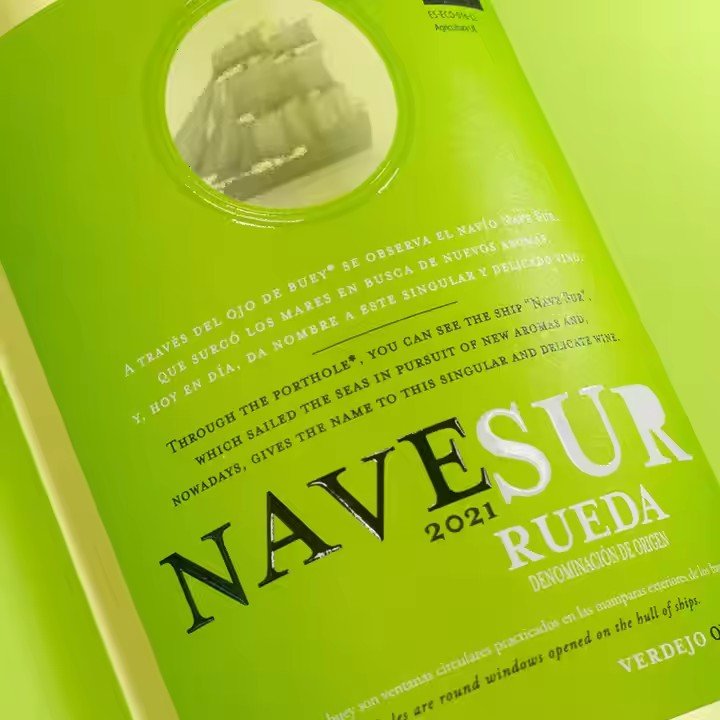

Limited-edition numbering: High-end limited releases (wines, art pieces) use aluminium labels with laser-etched serial numbers and anti-counterfeit patterns—both attractive and difficult to forge—boosting consumer trust.

Packaging & Container Decoration

Alcohol & beverages: Premium wines and whiskies often use embossed aluminium bottle labels that withstand refrigeration or heat without deforming. For example, aluminium labels on craft beer bottles remain clear and unwarped even after chilling, unaffected by condensation.

Cosmetics & personal care: Premium skincare packaging may feature aluminium labels with matte anodizing or mirror polishing for a sleek, high-end look that aligns with a “natural, luxury” brand positioning.

Medical & Laboratory: Precision and Hygiene at the Highest Standard

Medical and laboratory settings demand extreme stability, cleanliness, and corrosion resistance in labelling—qualities where aluminium excels.

Medical Device Marking

Sterile environment suitability: Surgical instruments and sterilisation equipment undergo repeated high-pressure steam sterilisation. Aluminium labels, welded or integrally formed with the device, can withstand 134 °C autoclaving without releasing harmful substances, meeting medical-grade hygiene standards.