professional in one-stop Packaging Labels solutions

e-mail:hxmdlz@hxmpackage.com

Shenzhen Huaxinmei Printing Co., Ltd.

Features

- Design

- why choose us

- Our Advantage

- How to use

- Our Services

FAQ

- Support

- certification

- payment

- customization

- Privacy Policy

In the thermal insulation sector, “gold labels” are most commonly associated with PrimaLoft® Gold insulation, designed for extreme-environment performance and widely used in professional outdoor gear and high-end apparel. The core material is modified ultrafine polyester fiber, with some premium versions incorporating aerogel composite technology to further push thermal limits.

The key advantage of PrimaLoft Gold lies in its thermal stability in cold and wet conditions. It offers a CLO value of approximately 0.92, comparable to 600–650 fill-power down, while maintaining an extremely low moisture regain of about 0.4%. Even when wet, it retains over 80% of its insulating performance and can air-dry within 2–3 hours, effectively solving the clumping issue typical of wet down. Its structure—coarse fiber cores wrapped with ultrafine fibers—creates sealed air chambers for heat retention. Some high-end variants add phase-change microcapsules, enabling automatic temperature regulation between –40°C and +15°C, making them suitable for polar expeditions and other extreme scenarios.

Material selection should be matched to fill weight and use case:

40 g: suitable for 10–20°C dynamic activities such as commuting or light hiking;

80 g: ideal for –5°C to +5°C cold and damp environments (southern winters, suburban camping);

200 g: designed for –20°C to –25°C severe cold (northeastern snowfields, outdoor construction).

A cost-effective alternative is 3M™ Thinsulate™ Gold insulation, with fibers as fine as 1/25 the diameter of human hair, providing 1.5× the static warmth of down. It is also Bluesign® 3.0 certified, with a significantly reduced carbon footprint, making it well suited for everyday commuting and light outdoor apparel.

In the biomedical field (e.g., colloidal gold test strips and diagnostic reagents), “gold labels” prioritize detection accuracy and material stability. Common materials include medical-grade colloidal gold, nitrocellulose (NC) membranes, and glass fiber membranes, all of which must comply with food-grade or medical-grade safety standards.

Medical-grade colloidal gold is the core labeling material. It should have a purity of 99.99%, a particle size of <15 nm, and a gold concentration of ≥1000 ppm, appearing as a uniform, transparent purplish-red solution. Its surface is easily functionalized to bind stably with antibodies or antigens, enabling rapid detection of HIV, hepatitis B virus, and pesticide residues in food. With high sensitivity, strong specificity, and simple operation, it is particularly suitable for primary healthcare settings and emergency screening. Storage requires protection from light and refrigeration, with a shelf life of up to six months.

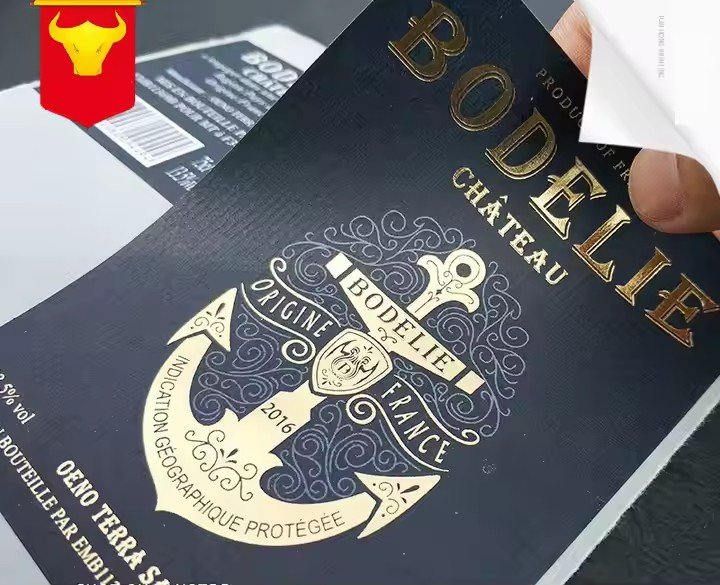

For decorative and identification applications—such as product nameplates, award plaques, and industrial labels—the core requirements are visual appeal and environmental resistance. Mainstream materials include PET plastic with high-gloss gold coatings and premium metal alloys, suitable for electronics, luxury packaging, and outdoor commemorative signage.

PET gold label material, based on polyethylene terephthalate, is coated with a high-gloss gold finish, combining a metallic appearance with the toughness of plastic. It can withstand temperatures from –40°C to +150°C, offers excellent tear and scratch resistance, and resists oils and mild cleaning chemicals, making it ideal for engine-bay labels and electrical nameplates. The adhesive typically uses a high-tack permanent glue, ensuring strong bonding to most substrates. Barcodes remain clearly scannable over long periods, and roll lengths of 400 m or 800 m can be customized for large-scale printing.

In the construction sector, gold-label products (such as gold-label moisture-resistant putty and insulation materials) focus on substrate reinforcement, moisture and mold resistance, and environmental safety. These products are typically cement-based or epoxy-based, modified with polymer additives, and are suitable for interior and exterior wall leveling as well as high-humidity protection.

Gold-label moisture- and mold-resistant putty uses high-quality cement and fine sand as the base, with added redispersible polymer powder and specialized anti-mold agents. A single coat can reach up to 5 mm thickness without cracking, offering strong adhesion to concrete and cement mortar substrates while effectively inhibiting mold growth—ideal for interior renovations in humid southern regions. Environmental compliance should meet GB 18582-2020, with formaldehyde ≤50 mg/kg and post-application indoor formaldehyde emission ≤0.08 mg/m³ after 12 hours of enclosure, ensuring a safe, flat base for subsequent finishes.

1. Core Selection Principles

Always prioritize application scenarios:

Extreme cold → aerogel-composite PrimaLoft Gold;

Medical diagnostics → high-purity colloidal gold with premium NC membranes;

Outdoor signage → stainless steel or bronze;

Damp walls → epoxy-based moisture-resistant putty.

Cost-performance balance comes next—everyday use does not require over-specification; for example, Thinsulate Gold can effectively replace higher-priced PrimaLoft in daily commuting wear.

2. Pitfall Avoidance Tips

Beware of counterfeit materials: for insulation, verify fill weight, CLO value, and environmental certifications on care labels to avoid ordinary synthetics being passed off as PrimaLoft;

Biomedical applications: require batch-to-batch consistency reports and avoid unqualified suppliers;

Decorative PET gold labels: test coating adhesion to prevent premature peeling;

Construction materials: always check environmental test reports to avoid products with excessive formaldehyde.

professional in one-stop Packaging Labels solutions

e-mail:hxmdlz@hxmpackage.com

Shenzhen Huaxinmei Printing Co., Ltd.

Fill in the form below to book a 30 min no-obligation consulting session.

I will reply within 24 hours.