- Specialty Coated Paper: Balancing Printing Precision and Glossy Texture

Specialty coated paper is considered the “standard premium option” in luxury stickers. By applying a special coating to the base paper, it offers varying degrees of gloss and surface texture while ensuring excellent color reproduction, making it the preferred choice for luxury logo stickers and cosmetic bottle labels.

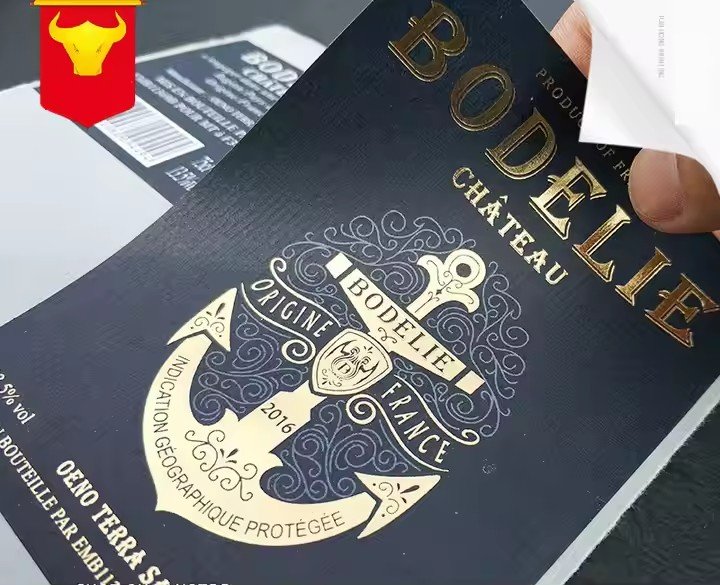

Its main advantages lie in the controllable surface finish and high color performance. The base paper, often made from wood pulp or cotton pulp, is dense with moderate stiffness. Through adjustments in coating composition and application, several subtypes are derived. For example, high-gloss coated paper features an extremely smooth surface with gloss exceeding 80%, resulting in bright and saturated colors after printing. This makes it ideal for stickers requiring strong visual impact, such as brand labels on premium liquor gift boxes. On the other hand, matte coated paper contains matting agents in the coating layer to reduce gloss below 30%, presenting a refined frosted texture. With no reflective interference, it conveys understated luxury and is commonly used for high-end perfume or skincare labels. When paired with hot-stamping, it creates an elegant contrast of “matte background + metallic shine.”

Additionally, some specialty coated papers include functional coatings that enhance luxury properties. Scratch-resistant coatings can achieve surface hardness above 4H, preventing damage during transport or use. Waterproof coatings allow application in humid environments, such as bathroom diffusers or car fragrances, ensuring print stability and mold resistance. For instance, a luxury beauty brand once used 128g matte coated paper as the base for a limited-edition lipstick sticker. Combined with spot UV coating, the brand logo appeared slightly raised with subtle gloss against the matte background—retaining a premium matte feel while adding tactile refinement.

- Metallic-Finish Paper: Built-In Luxury Shine

Metallic-finish paper naturally exudes metallic luster or texture without the need for additional hot-stamping, making it the most direct way to convey “luxury.” It is especially suitable for holiday gift stickers and premium electronic product decals, instantly elevating product appeal.

Its key traits are inherent gloss and diverse textures, typically achieved through two processes:

Metal foil lamination: Ultra-thin layers of aluminum or copper foil are laminated onto the base paper, creating foil paper with near-authentic metallic shine. It comes in gold, silver, bronze, and more, with good ductility for mild curved applications. For example, embossed gold foil stickers on premium chocolate boxes achieve dazzling light reflections without additional decoration.

Metallic pigment coating: By adding aluminum or pearlescent powder into the coating, pearlescent metallic paper is produced. This has a softer shimmer, more “pearl-like” rather than the mirror-like reflection of foil paper, suitable for subtler luxury effects. For example, silver pearlescent paper stickers on premium stationery boxes reveal a gradient luster under natural light, avoiding harsh glare.

From a performance standpoint, metallic papers generally have higher stiffness and abrasion resistance than coated papers, ensuring long-lasting shine. However, foil papers may crack (“foil break”) when folded, making them better for flat or gently curved surfaces, while pearlescent papers are more foldable and versatile.

- Cotton Fiber Paper: Natural Texture with Premium Appeal

Cotton fiber paper, made primarily from cotton pulp (usually 70%+ content), is prized for its natural texture, soft touch, and eco-friendly qualities. It is widely used in luxury cultural products and premium packaging, embodying a sense of “subtle luxury.” When combined with techniques such as hot stamping or embossing, its organic beauty is further enhanced.

Its advantages lie in natural texture and sustainability. Cotton fibers are long and soft, producing paper with delicate fiber patterns rather than the smooth, industrial look of regular paper. This tactile naturalness creates warmth and authenticity. For example, a premium tea brand used 150g cotton fiber paper for its gift box stickers. By retaining cotton’s natural texture, printing only the brand name in light brown ink, and adding gold embossed floral patterns, the design highlighted the paper’s organic feel while enhancing its luxurious appeal—perfectly aligning with the tea’s “natural and premium” positioning.