- Food and Beverage Industry: Combining Protection with Premium Appeal

In the food and beverage industry, labels are required to provide both protection and visual appeal, and foil labels meet both demands. The dense metallic structure effectively blocks moisture, oxygen, and grease, preventing labels from smudging or peeling due to humidity or food oils. Therefore, foil labels are widely used on pre-packaged foods (e.g., frozen dumplings, ready-to-eat chicken breasts) and canned products (e.g., luncheon meat, canned fruit), ensuring that essential information like production dates and ingredient lists remains clear throughout the product’s shelf life.

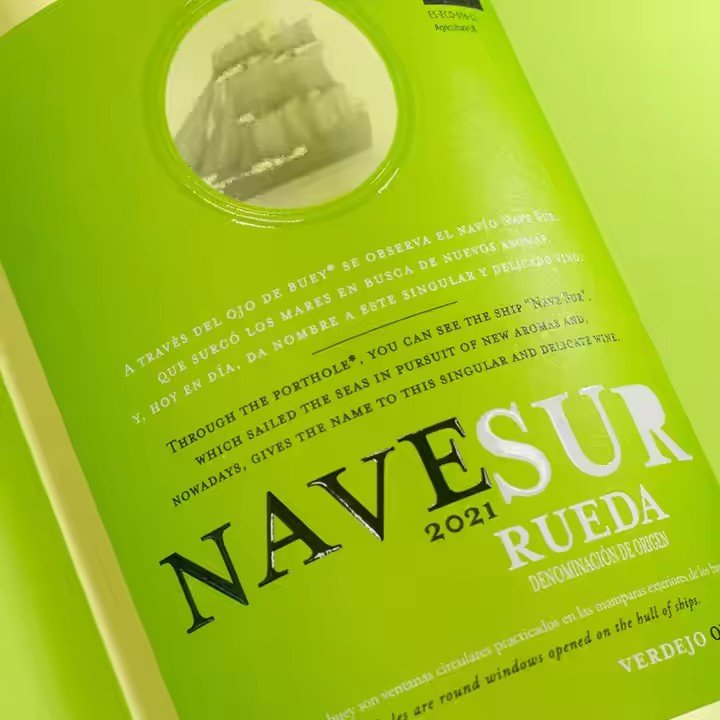

For premium appeal, the metallic sheen of foil labels can be enhanced through gold stamping or matte finishes, creating a high-end look. Examples include gold foil labels on luxury chocolate gift boxes to highlight exclusivity; aluminum foil labels on aged Pu’er tea cakes for moisture protection and laser-engraved branding; and foil neck labels on high-end wine bottles, which convey winery information and incorporate special textures to prevent tampering, combining security with aesthetics.

- Pharmaceutical Industry: Ensuring Safety and Compliance

The pharmaceutical industry demands high stability and anti-counterfeiting performance from labels. Foil labels are well-suited for these requirements. During drug production, their chemical resistance allows them to withstand disinfectants like alcohol and iodine, while tolerating extreme environments such as high-temperature sterilization (121°C wet heat) and cold storage (-20°C for vaccines). This ensures that drug names, batch numbers, and expiration dates remain legible, preventing medication errors caused by damaged labels.

For anti-counterfeiting, pharmaceutical foil labels can integrate multiple technologies: for instance, prescription drug foil labels may use holographic stamping to display dynamic patterns from certain angles, while vaccine packaging can embed RFID chips, enabling full traceability of production and transport, thereby reducing counterfeit circulation and ensuring medication safety.

- Automotive Industry: Adapting to Extreme Conditions and Long-Term Identification

Automotive labels face extreme conditions, including high temperatures, abrasion, and strong vibrations. Foil labels’ durability makes them ideal for vehicle parts. On engine components like blocks and exhaust manifolds, where temperatures can exceed 300°C, standard paper labels would burn quickly, whereas high-temperature foil labels can be directly affixed or riveted, marking model numbers and batch codes for maintenance traceability.

For chassis and electrical systems, foil labels resist water, oil, and impact from road debris, marking wiring harnesses or installation parameters. In electric vehicle battery packs, flame-retardant foil labels indicate capacity and voltage, maintaining legibility even at high operating temperatures, ensuring vehicle safety.

- Electronics Industry: Precision and Interference Resistance

Electronic components are small and operate in complex environments with high temperatures and electromagnetic interference. Foil labels’ compact size and EMI resistance are advantageous. On PCB boards, micro foil labels can be laser-etched with component numbers and soldering parameters, tolerating 260°C soldering without generating electromagnetic interference.

In consumer electronics, foil labels on internal cooling modules of laptops or smartphones indicate heat dissipation and maintenance cycles, aiding service personnel. Industrial electronics (e.g., inverters, sensors) use foil labels on housings to resist dust, oil, and corrosive environments, keeping device numbers and calibration dates legible for lifecycle management.

- Cosmetics Industry: Enhancing Visual Appeal and Brand Recognition

Visual attraction is a key competitive factor in cosmetics, and foil labels enhance product aesthetics. In makeup, gold foil labels on lipstick tubes or metallic logos on eyeshadow palettes emphasize delicacy—e.g., rose-gold foil labels cater to young consumers’ preference for “affordable luxury.” In skincare, embossed foil labels on serum or cream bottles provide tactile texture and reinforce brand identity. Cosmetic gift boxes can feature scenario-based designs, such as snowflake cutouts on Christmas editions, interacting with light to evoke festive ambiance and stimulate purchasing desire. - Aerospace Industry: Meeting Extreme Conditions and High Reliability

Aerospace components demand extreme environmental adaptability and long-term reliability, and foil labels are among the few solutions that meet these standards. On aircraft, engine turbine blades and high-temperature body parts require material codes and fatigue life information; foil labels can be sintered onto metal surfaces, resisting temperatures above 1000°C and strong airflow, keeping information intact during flight.

For spacecraft, labels on solar panels or rocket propulsion components must withstand vacuum, cosmic radiation, and extreme temperatures (-180°C to 150°C). Foil labels’ durability ensures that critical data remains readable throughout the spacecraft’s operational life (typically 5–10 years), supporting mission safety.