After the labels are produced, it is necessary to evaluate the products, assess the quality of the labels, and ensure that the overall quality meets the qualified standards. This is a crucial step after production and is a prerequisite for checking whether the products are qualified.

Visual Inspection

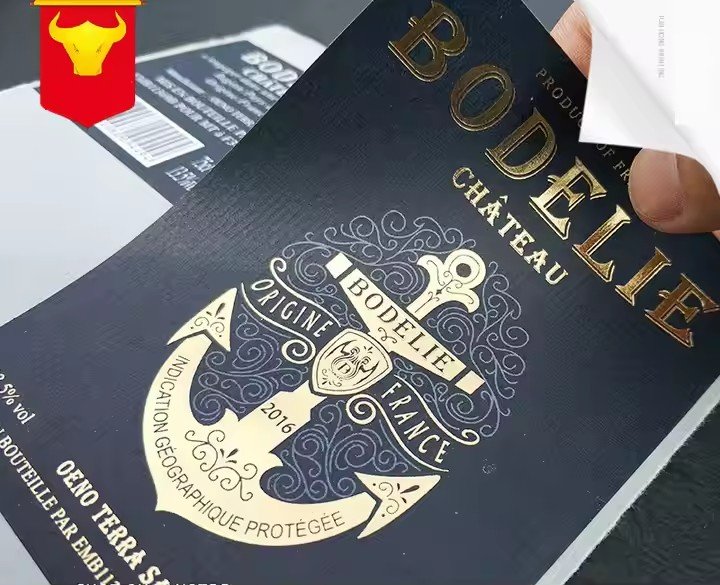

Direct Observation: Evaluators conduct a comprehensive visual inspection of the overall appearance of the label samples with the naked eye. They check whether the patterns and text are clear and complete, whether the colors meet the design requirements, and whether there are obvious printing defects such as stains and scratches. At the same time, they observe whether the label surface is flat and whether there are issues like wrinkles and bubbles. For the produced products, careful observation is needed to identify those with immediate defects, and these defective label products should be removed to ensure product quality.

Comparison with Sample Cards: Carefully compare the label samples with the standard sample cards or design originals. Focus on checking aspects such as colors, pattern details, text content, and layout to ensure that the labels are consistent with the standards or originals. By comparing with the sample cards, products that do not match the sample cards should be removed to ensure a high degree of consistency.

Physical Property Tests

Dimension Measurement: Use measuring tools such as calipers and rulers to accurately measure the length, width, thickness, etc., of the labels to determine whether they are within the specified tolerance range. By measuring the dimensions and comparing them with the production – specified dimensions, if the produced dimensions are too small or too large and do not meet the requirements, the product should be removed. Dimension measurement is to ensure that the product sizes are consistent, minimizing deviations as much as possible.

Adhesion Tests

Initial Adhesion Test: Use the ball – rolling method. Roll steel balls of different sizes on the inclined surface of the label and observe the position where the steel balls stop rolling to determine the initial adhesion of the label.

Permanent Adhesion Test: Stick the label on a standard test plate, hang a weight of a certain mass, and record the time when the label falls off the test plate to evaluate its permanent adhesion.

Peel Strength Test: Use an electronic universal testing machine to peel the label from the adhered object at a certain speed and angle, measure the required force, and obtain the peel – strength data.

Scratch Resistance Test: Use a scratch – resistance testing machine to scratch the label surface with a specific scratching tool at a certain pressure and speed. Evaluate its scratch – resistance performance by observing the scratch conditions and the degree of ink peeling on the label surface. This is a more in – depth test to check water resistance, scratch resistance, friction resistance, etc., to ensure the performance of label products. For example, for the labels of skin – care products, these products are usually placed next to the sink. Consumers usually touch the labels on the bottles with wet hands after washing their faces. Then these labels are likely to fade or fall off due to insufficient adhesion when wet. This is why testing is necessary to determine whether the produced products are qualified.

Folding Resistance Test: Use a folding testing machine to bend the label at the specified angle and number of times, and check whether there are phenomena such as cracks, breaks, or ink peeling. The folding – resistance test can quickly check the product quality. If cracks are found in the product through the test or the ink disappears after folding, then the product needs to be re – produced. Pay attention to the ink used and choose ink products that can remain clear even after being exposed to rain or folded, otherwise there may be some negative impacts.

Chemical Property Tests

Water Resistance Test: Immerse the label samples in water and observe the changes of the labels at different time points, such as whether there is fading, ink bleeding, paper deformation, or delamination, etc., to evaluate the water – resistance of the labels.

Chemical Resistance Test: According to the chemical substances that the label may come into contact with, such as acids, alkalis, and organic solvents, dip a cotton ball in the corresponding chemical reagent and gently wipe the label surface. Observe whether the label shows phenomena such as discoloration, dissolution, or foaming to judge its chemical resistance.

Function Tests

Information Recognition Tests

Barcode Scanning Test: Use a barcode scanner to scan the barcode on the label to check if the barcode information can be read quickly and accurately, ensuring the correct coding and readability of the barcode.

QR Code Recognition Test: Use a mobile phone or professional QR – code scanning equipment to scan the QR code on the label to check if it can smoothly link to the specified web page or obtain relevant information.

Anti – counterfeiting Function Test: For labels with anti – counterfeiting functions, use corresponding anti – counterfeiting detection tools and methods. For example, use a fluorescent detection lamp to detect fluorescent anti – counterfeiting inks, an infrared detector to detect infrared anti – counterfeiting technologies, or verify the authenticity of the anti – counterfeiting code to verify the effectiveness and reliability of the anti – counterfeiting function.

Professional Instrument Tests

Color Difference Meter Detection: Use a color difference meter to accurately measure the color of the label. By measuring parameters such as Lab values, obtain the color – difference data between the label and the standard color, and accurately determine the degree of color deviation.

Spectral Analyzer Detection: For labels with special requirements, such as those containing special pigments or requiring detection of specific components, a spectral analyzer can be used to detect the label, analyze its components and spectral characteristics, and ensure they meet relevant standards and requirements.