I. Manufacturing and Processing Industry: From Production Traceability to Finished Product Protection

The manufacturing industry is the core application field for process stickers. They are mainly used for production process management, product identification, and finished product protection, covering sub-sectors such as metal processing, plastic manufacturing, and hardware parts. Stickers enable full-chain traceability and product protection.

- Metal Processing Industry: High-Temperature Resistance and Scratch-Proof Labels

In metal processing (e.g., stainless steel plate cutting, aluminum alloy stamping, hardware forging), the environment involves high temperatures (welding, coating up to 200–300℃), oil, and scratches. Process stickers must be heat-resistant, oil-proof, and highly legible:

Production Traceability Stickers: Applied to raw metals (e.g., stainless steel coils, aluminum ingots) using high-temperature-resistant PET stickers. UV printing marks material grade (e.g., 304 stainless steel, 6063 aluminum alloy), dimensions (e.g., 1.2m × 2.4m), production batch, and manufacturer details. Stickers must withstand short-term exposure up to ≥260℃ and remain legible in oily environments to prevent misidentification of raw materials.

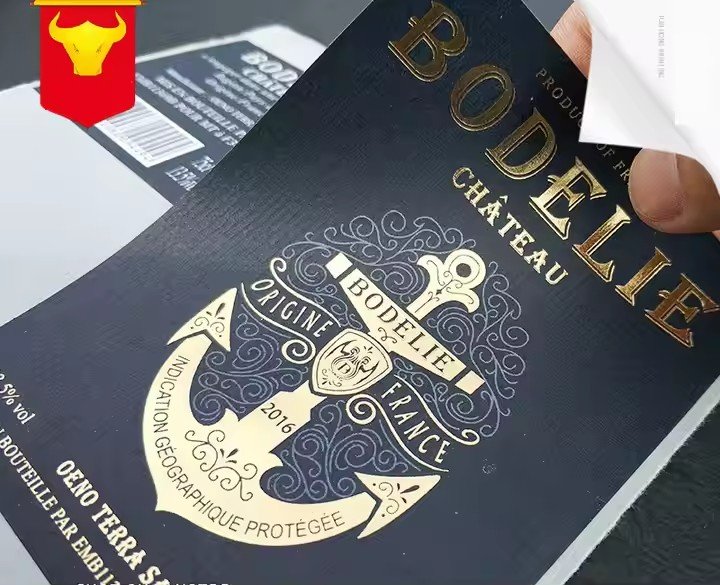

Finished Product Protection Stickers: For finished products (e.g., stainless steel sinks, aluminum window frames), PE protective film + printed layer composite stickers are applied before shipping to prevent scratches (film thickness ≥0.05mm, scratch resistance ≥3H). They can also display installation instructions (e.g., “Handle with Care,” “Installation Direction”). Premium products may use brushed metallic foil stickers that provide protection while enhancing product aesthetics.

- Plastic Manufacturing Industry: Waterproof and Removable Labels

In plastics (e.g., injection-molded parts, extruded profiles, plastic pipes), stickers must adapt to low surface adhesion while meeting waterproofing, aging resistance, and removability requirements:

Product Parameter Stickers: On PVC or PPR pipes, BOPP waterproof stickers are applied with details such as size (e.g., DN25), pressure rating (e.g., 1.6MPa), and standards (e.g., GB/T 18742). Stickers must pass water-resistance tests (24-hour immersion without detachment or blurring) and resist aging outdoors for ≥5 years.

Temporary Protective Stickers: For injection-molded parts (e.g., appliance housings, automotive interior parts), removable acrylic adhesive stickers protect surface gloss. These require low adhesion (peel strength ≤5N/25mm), easy removal without residue, and no interference with painting or assembly processes.

II. Electronics and Electrical Industry: High Precision and Functional Applications

The electronics industry demands extreme precision, with stickers serving functions such as conductivity, insulation, and heat resistance in PCB boards, consumer electronics, and appliances. This is one of the most technically advanced application areas.

- PCB Industry: Conductive and Insulating Stickers

For PCB boards (e.g., smartphone motherboards, graphics cards, control boards):

Conductive Copper Foil Stickers: Applied to grounding areas using rolled copper foil + acrylic adhesive to provide EMI shielding (≥30dB). Must achieve high-precision die-cutting (tolerance ≤±0.1mm) to fit irregular PCB areas.

Insulating Heat-Resistant Stickers: Polyimide (PI) stickers are applied to solder joints or exposed copper wires, withstanding up to 280℃ short-term. They have insulation strength ≥20kV/mm, preventing short circuits and tolerating reflow soldering heat.

- Consumer Electronics Industry: Decoration and Information Labels

In smartphones, tablets, and earphones, stickers serve branding, information display, and aesthetics:

Brand Logo Stickers: Hot-stamped PET stickers (gold/silver) applied to device surfaces. Cold-pressed application ensures smooth edges (tolerance ≤±0.05mm) and wear resistance ≥4H (no fading after 50 rub tests).

Information Stickers: VOID tamper-proof stickers on packaging or device interiors display SN codes, production dates, and origins. Once removed, they reveal “VOID,” preventing tampering or channel conflicts. High-end devices may use NFC chip stickers for authenticity and warranty verification via smartphones.

- Home Appliances Industry: Heat-Resistant and Warning Labels

Appliances such as refrigerators, air conditioners, and ovens require stickers that withstand heat and long-term use while providing warnings and functional labeling:

Heat-Resistant Warning Stickers: Ceramic-coated PET stickers inside ovens or microwave doors print warnings (e.g., “No Metal Containers,” “High Temperature Hazard”). They endure ≥220℃ continuous exposure, resist oil, and are easy to clean.

Functional Stickers: Durable PVC stickers on control panels (e.g., AC remotes, washing machine dashboards) display button functions. A scratch-resistant coating (≥3H) ensures durability over 100,000 presses, with anti-fingerprint properties to maintain clarity and aesthetics.