- Before Design: Understand Needs and Choose the Right Materials

(1) Know the Purpose and Brand Positioning

Wine bottle stickers serve to:

Share product info

Show the brand

Help with marketing

Before designing, talk clearly with the brand to avoid unnecessary or complex designs.

Examples:

Basic info: Use small fonts or layered layouts to save space.

Brand look: Focus on key brand visuals. One whisky brand simplified their family logo to a line icon, which cut space by 40% but made it easier to recognize.

Marketing ideas: Use QR codes instead of long descriptions. This saves space and makes the design more interactive.

(2) Match Material and Size Properly

Choosing the right paper is key to saving material.

Tips:

Use standard paper sizes. Custom sizes can increase waste and cost by 30%-50%.

One craft beer brand changed label size slightly, cutting material cost by 18%.

- During Design: Make Smart Layouts and Use Efficient Techniques

(1) Layout Design: Use Space Wisely

Modular Layout Strategy

Split the sticker into parts:

Top: Logo + security mark (simple gold print)

Middle: Main info in grid format with tight line spacing

Bottom: QR code + batch number (QR at least 20×20mm)

Simple Fonts and Graphics

Fonts: Use clear, non-fancy fonts. Use wider fonts for better space control.

Graphics: Replace detailed images with icons. One wine brand cut a 12-color grapevine to a 3-color block, increasing material use by 25%.

White space: Leave 10-15% of empty space to avoid cutting errors.

(2) New Printing Layout Methods

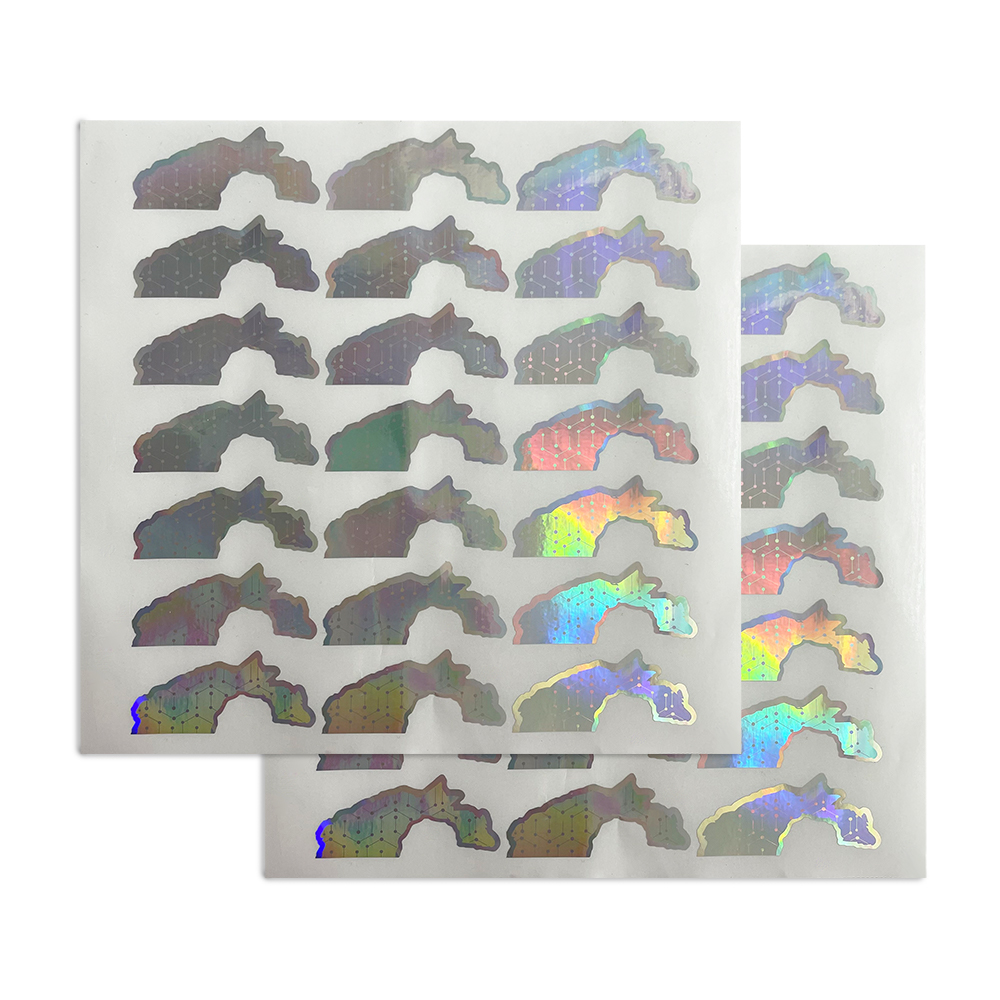

Mixed-Shape Layouts

Put different-shaped stickers on the same sheet:

Rotate square stickers to fit more on the sheet

Use “one-cut” tools to reduce cutting waste from 15% to about 5%

Seamless Repeating Designs

For full-background labels (like stars or marble), use repeating patterns to reduce leftover edges.

One vodka brand used repeatable star patterns and saved 22% in label cost.

- During Production: Match Process with Design and Control Quality

(1) Improve Printing Efficiency

Use Better Ink

Water-based ink dries 30% faster than solvent-based.

Mix spot color + CMYK to use less ink overall (cut by 28%).

Tune Printing Machines

Adjust tension by paper weight to avoid paper wrinkles (waste down from 9% to 3%).

Use satellite flexo printers for more precise prints (cutting error margin reduced by 50%).

(2) Smart Cutting and Trimming

Digital Cutting Layouts

Use AI to plan cuts, fit big stickers first, then small ones. This cut waste from 23% to 11%.

Use laser cutters for tricky edges—precision improved, and rework cut from 15% to 4%.

Control Paper Tension When Cutting Rolls

Use automatic tension controls so the paper doesn’t stretch (size error reduced to ±0.5mm).

Use a “3-step quality check” before mass production: self-check, peer-check, and expert-check. Measure diagonals and print alignment on 50 test samples.

- Sustainable Design: Reuse and Eco-Friendly Materials

Use recyclable paper, inks, and smart design strategies to reduce waste and protect the environment while still keeping the label attractive and functional.