In the Label Design Stage

Clarify the Purpose and Information Structure of the Label

Clear Purpose: In terms of design style, determine the label’s pattern, color, and slogan. Figure out how to make it more aesthetically pleasing, what font to use, and where to place the slogan to make it more prominent and easier for consumers to remember. Also, clarify all information to enable consumers to have the right to know about the product.

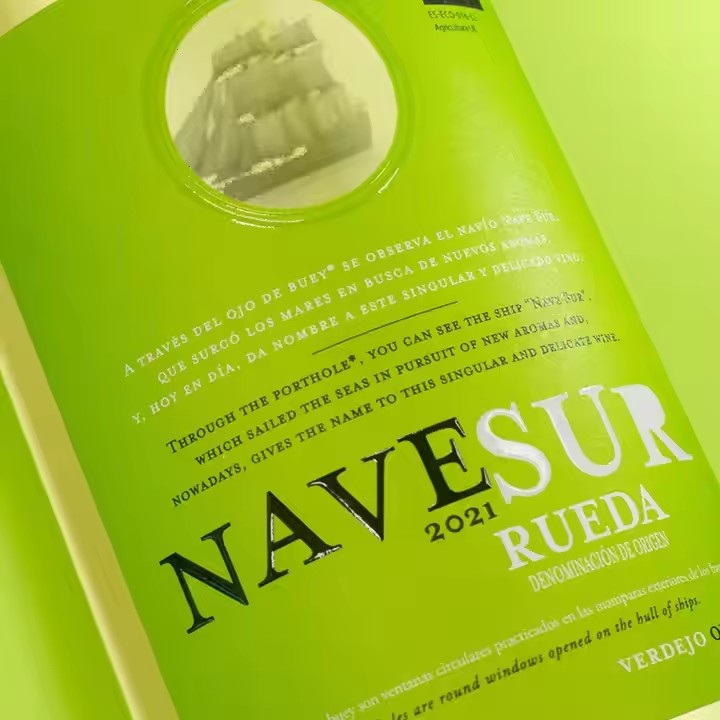

Information Structure Planning: Reasonably arrange the information layout. For example, regarding product information such as the product name, logo, and quality, decide where to place the design pattern appropriately. Plan the relevant product information well. Through design, by choosing what kind of font, color, pattern, slogan, and information structure to use, make it easier for consumers to remember the product name, let more consumers know about the brand, and encourage them to purchase the product.

Design in Line with Standards and Regulations:

Regulatory Compliance: Different industries have different regulations to abide by. For example, for pharmaceuticals, it is necessary to note on the bottle the name, ingredients, properties, indications, specifications, dosage, adverse reactions, contraindications, precautions, etc., to avoid misleading consumers and causing poisoning. Each product and industry has its own rules, and products should be made to comply with industry rules on product labels or outer packaging.

Industry Standard Matching: In addition to complying with industry regulations, label packaging should also clearly indicate additional product ingredients. For example, in the bedding industry, indicate what ingredients are in the quilt, such as whether it is made of fiber fabric or pure cotton.

Pay Attention to Readability and Aesthetics

Text Design: Select clear and legible fonts, and reasonably determine the font size according to the label size and reading distance. For example, for small product labels like jewelry labels, the text should be small enough to fit the label size, but still ensure clear readability at normal vision and an appropriate distance. Avoid using overly fancy or unreadable fonts, and have a sharp color contrast, such as black text on a white background, to ensure that the text content stands out.

Graphic Elements: The rational use of graphic elements can enhance the label’s attractiveness and information transmission ability. For example, on the labels of environmentally friendly products, green leaves, the earth and other graphics can be used to visually convey the product’s environmental protection attributes. The graphic design should be simple and clear, in line with the product characteristics and brand image, and avoid overly complex graphics that cause information confusion. At the same time, the graphics and text should be coordinated with each other to form an organic whole and enhance the label’s aesthetics.

In the Label Production Stage

Select High-Quality Materials

Durability Consideration: Select appropriate label materials according to the product’s usage environment and lifespan. For outdoor products such as building materials and gardening tools, materials with waterproof, sunscreen, and abrasion-resistant properties are required. For example, labels made of polyester (PET) material have good weather resistance and chemical stability, and can maintain the integrity and readability of the label for a long time in outdoor environments.

Material Matching with the Product: The texture of the label material should also match the product. For high-end cosmetics or luxury goods, the label can use materials with a glossy and textured feel, such as silk-textured labels or stickers with a metallic texture, to enhance the overall quality of the product. For ordinary daily necessities such as cleaning products, ordinary paper labels can be selected, but the quality of the paper should be ensured to prevent the label from being easily damaged or faded during use.

Adopt Advanced Printing Technology

Improvement of Printing Precision: Advanced printing technologies such as digital printing and flexographic printing can improve the printing precision of labels. Digital printing can achieve high-precision image and text printing with high color reproducibility. For example, when printing a product’s brand logo, digital printing can accurately present the brand’s colors and details, making the logo on the label clearer and more eye-catching, enhancing the brand image and product quality perception.

Application of Special Effects: Use some special printing effects to enhance the quality of the label. For example, gold stamping and silver stamping technologies can be used to highlight the product name or important information on the label, giving a high-end and delicate feeling. For some products that need anti-counterfeiting, anti-counterfeiting printing technologies such as anti-counterfeiting inks and holographic anti-counterfeiting printing can also be used, which can not only enhance the product’s quality image but also effectively prevent counterfeiting.

In the Label Management Stage

Quality Control and Inspection

Production Process Monitoring: Establish a quality monitoring mechanism during the label production process. Regularly check the running status of printing equipment to ensure the stability of printing quality. For example, conduct real-time monitoring of printing colors to ensure color consistency of labels through a color management system. At the same time, check the cutting accuracy of labels to prevent large deviations in label size.

Finished Product Inspection: Conduct strict inspections on the completed labels. Check whether the label content is complete and accurate, and whether the printing quality meets the requirements, such as whether there are blurring, fading, ghosting and other phenomena. The sampling inspection method can be adopted to check the label samples according to a certain proportion. For the production of a large number of labels, a full inspection process can also be added to ensure that each label meets the quality standards.

Storage and Protection of Labels

Optimization of Storage Environment: Provide a suitable storage environment for labels to avoid damage. Labels should be stored in a dry, cool and ventilated environment to prevent moisture, mildew or direct sunlight. For some label materials that are sensitive to temperature and humidity, such as thermal labels, strictly control the temperature and humidity of the storage environment to extend the shelf life of the labels.