Reasonable Structural Design

Precisely Fit the Product: The structure of a high-quality gift box should be customized according to the shape, size, and characteristics of the product. For example, for a bottle of high-end wine, the inner partition of the gift box will closely fit the body of the bottle, and there are specially designed slots at the bottom and neck of the bottle, so that the wine bottle won’t shake inside the box and can effectively prevent collision damage during transportation. For a set of exquisite tea sets, the gift box will have a layered design, fixing the teapot, teacups, etc. in different positions respectively, which is convenient for display and ensures safety.

Easy to Open and Close: Whether it’s a flip-top, drawer-type, or top-and-bottom cover gift box, it should be easy and smooth to open and close. Take the flip-top gift box as an example. The opening and closing angle of the lid is moderate, usually between 120 and 150 degrees. This is convenient for displaying the product and won’t cause the lid to be easily damaged due to an overly large angle. Meanwhile, the connection parts between the lid and the box body, such as magnetic attraction and buckle devices, should have just the right strength. The magnetic attraction is strong enough to keep the lid tightly closed, and the buckle is easy to operate and firm. This is often used in the outer packaging of some luxury goods. Using magnetic attraction can safely protect the products inside the gift box and prevent them from falling out during transportation.

Good Stability: The gift box should be stable when placed and won’t tip over easily. This is especially important for some gift boxes with a high center of gravity or irregular shapes. For example, for a gift box with a relatively high decorative shape, the bottom will be designed to be relatively wide and thick, or a special weighting method will be adopted to ensure that it can be stably placed on a flat surface like a table.

High-Quality Materials

Good Texture of Outer Materials: High-quality gift boxes usually choose high-quality paper, wood, leather, or plastic as outer materials. If it’s paper, special paper with enough thickness and stiffness will be chosen, such as pearl paper or art paper with a grammage of 300 – 400 grams per square meter. These papers have a shiny surface and a delicate touch, which can enhance the grade of the gift box. If it’s a wooden gift box, wood with beautiful texture and solid texture, such as walnut wood or cherry wood, will be used, and it has been finely polished and treated to make the wood surface smooth without burrs.

Strong Function of Inner Materials: Inner materials are mainly used to protect products and improve the display effect. For products that are afraid of scratches, such as electronic products, the inner layer of the gift box will use soft flocking materials or flannel, which can effectively prevent the product surface from being scratched. For food gift boxes, the inner layer materials will choose materials that meet food hygiene standards, such as food-grade white cardboard or laminated paper, to ensure the safety and hygiene of food.

Good Quality of Auxiliary Materials: Glue is a commonly used auxiliary material in making gift boxes. High-quality gift boxes will use environmentally friendly and long-lasting adhesive glue. For example, hot melt glue can maintain good adhesion after solidification and won’t have the phenomenon of glue peeling off due to long time or environmental changes. If the gift box has decorative ribbons, the material of the ribbons should be soft, shiny, and not easy to fluff silk or high-quality polyester fiber, and the width and length should also meet the requirements of design aesthetics.

Exquisite Printing

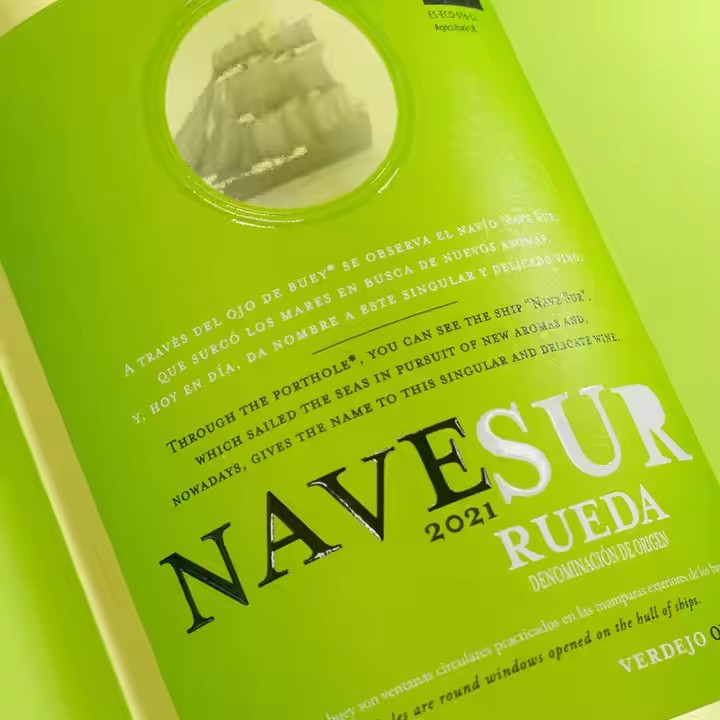

Clear and Accurate Patterns: The patterns and words on the gift box should be clearly distinguishable without blurring, ghosting, or color fading. During the printing process, for fine patterns and small-sized words, the resolution usually reaches more than 300dpi. For example, on some gift boxes with traditional patterns (such as Chinese paper-cut patterns, Western classical patterns), each pattern’s lines should be delicate and smooth, and the color transition is natural. For the text parts such as brand logos and product information, the font is standardized, the size is appropriate, and it can accurately convey information.

Vivid and Long-Lasting Colors: High-quality gift boxes have a high color reproduction rate and can accurately present the design intention. Advanced printing technologies, such as four-color printing (CMYK) or spot color printing, are adopted to ensure color accuracy. Moreover, after surface treatment, the colors can be maintained for a long time and won’t fade due to factors such as light and friction. For example, some gift boxes printed by UV printing and varnishing still have vivid colors after long-term display.

Match the Brand and Theme Style: The printed content should match the brand image and product theme represented by the gift box. If it’s a gift box of a high-end luxury brand, the printing style will tend to be simple and elegant, and the colors will mainly be noble tones such as gold and silver. If it’s a children’s gift box, the printed patterns will be full of childishness, with rich and lively colors, and there may be cartoon images, fairy tale scenes, and other contents.

Outstanding Gold Stamping and Silver Stamping Techniques: Gold stamping and silver stamping are high-end decorative techniques commonly used in making gift boxes. The excellent gold stamping and silver stamping effects should be uniform, shiny, and firm. The edges of the gold stamping patterns are clear without burrs or missing gold. Under the light, the gold stamping part will reflect a bright luster, increasing the luxury of the gift box. The silver stamping technique is similar. The silver part has a delicate texture and coordinates well with other colors. For example, on some high-end cosmetic gift boxes, the brand names and logos usually adopt the gold stamping technique to make them stand out among many products.

Exquisite Embossing and Relief Techniques: Embossing and relief techniques can add texture and a three-dimensional effect to gift boxes. For the embossing technique, the texture should be clear, natural, and of moderate depth. For example, on a gift box with a leather texture embossed, the leather texture looks like real leather, with good tactile and visual effects. The relief technique is more three-dimensional. The patterns can protrude from the surface of the gift box, and the height is generally between 1 and 3 millimeters. The protruding parts are smooth and exquisite, giving a beautiful artistic feeling.